Table of contents

- FEM simulation

-

How does FEM simulation work?

- What is the finite element method?

- What are the mathematical principles behind the FEM?

- How are the deformation and stress of a component calculated?

- Your contact

FEM simulation

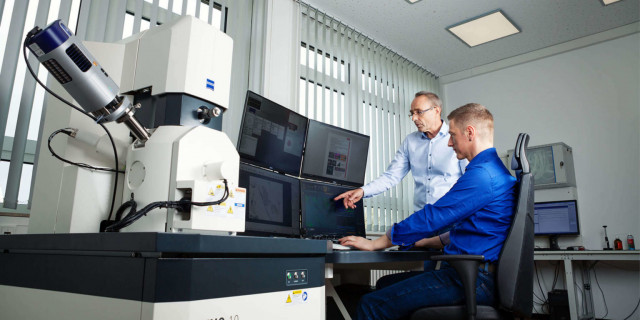

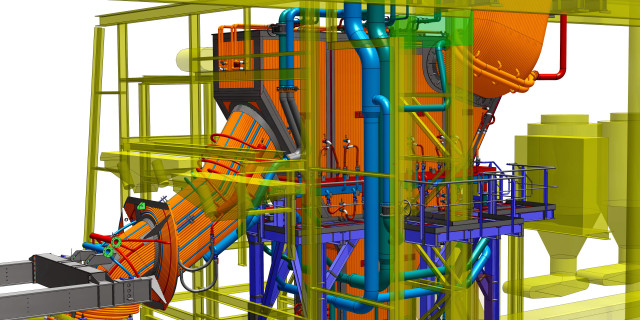

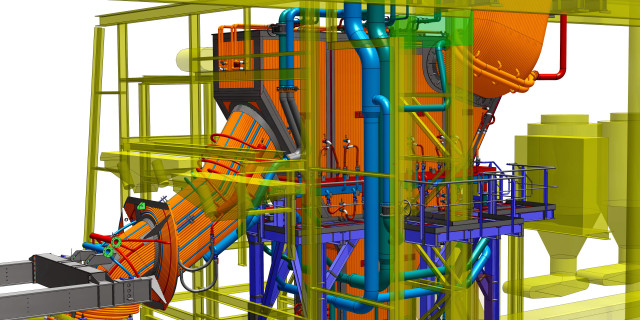

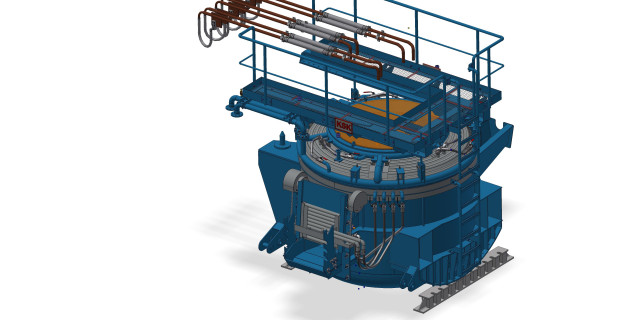

The finite element method (FEM) has established itself as one of the leading technologies for calculating and simulating physical systems. In modern industry, FEM simulation enables the precise analysis and prediction of deformations, stresses, and other physical variables in complex components. This comprehensive method is used in numerous industries, including the steel industry for the development of water-cooled plant systems and apparatus, and offers decisive advantages to companies such as KSK GmbH in Haltern am See.

How does FEM simulation work?

What is the finite element method?

The finite element method is a numerical method for solving differential equations that describe physical phenomena. It is based on the discretization of geometries into a large number of smaller, simpler elements, such as triangles or quadrilaterals. These elements are used to create a system of equations that approximates the physical behavior of the entire system. By using approach functions that must satisfy certain mathematical conditions, the FEM can calculate the displacements, stresses, and deformations of a component.

What are the mathematical principles behind the FEM?

The FEM is based on the method of weighted residues and the principle of virtual work. These mathematical approaches make it possible to convert the differential equations that describe the physical behavior of a system into a system of algebraic equations. By solving this system of equations, the physical quantities, such as stress and displacement, can be determined in the discrete elements of the model. The fineness of the subdivision and the density of the mesh are decisive for the accuracy of the FEM simulation.

How are the deformation and stress of a component calculated?

The deformation and stress of a component are calculated using FEM by applying loads and boundary conditions to the discretized model. The FEM simulation solves the resulting system of equations, taking into account the laws of physics, to determine the resulting stresses and deformations. The choice of boundary conditions is crucial here, as they define the physical limits of the system and influence the accuracy of the simulation.

Your contact

Prof. Dr.-Ing. Andreas Wichtmann

Simulation and FEM

+49 (0) 2364 10539-0

What are the industrial applications of FEM?

How is FEM used in the steel industry?

In the steel industry, FEM is used to optimize and analyze components that are exposed to high loads. Simulation enables engineers to examine the stress distribution within steel structures and identify potential weak points. FEM enables companies such as KSK GmbH in Haltern am See to extend the service life of their products and ensure the safety of their structures.

What role does FEM play in the metal construction industry?

FEM is an indispensable tool for metalworkers, as it enables the precise analysis and optimization of metal structures. In the metal construction industry, the finite element method is used to test the load-bearing capacity and stability of structures. For example, FEM simulation can be used to evaluate the effects of physical loads on load-bearing elements and thus increase the efficiency of the structure.

How does FEM support water-cooled plant systems?

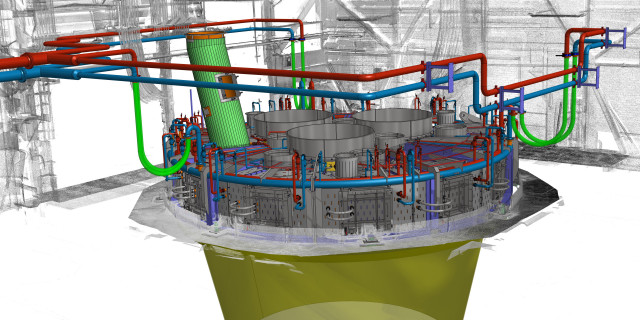

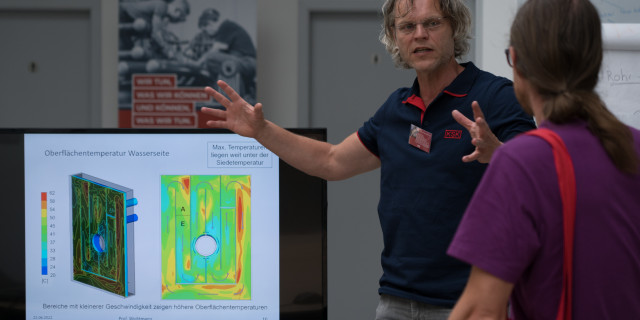

Water-cooled plant systems benefit significantly from FEM simulation, as it enables detailed analysis of thermal and mechanical stresses. These systems require careful planning and optimization to ensure maximum efficiency and longevity. FEM enables engineers to simulate thermal expansion and the resulting stresses in the system components in order to make design decisions that improve performance and reduce operating costs.

How is an FEM simulation created?

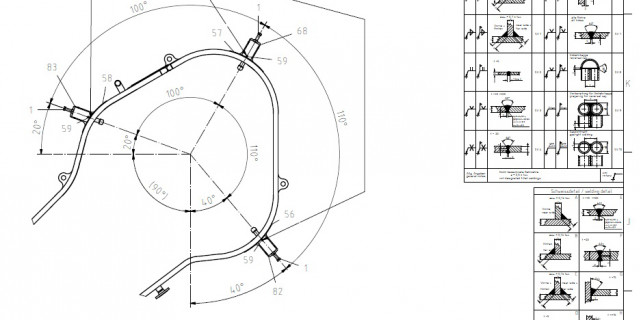

What steps are involved in discretization in FEM?

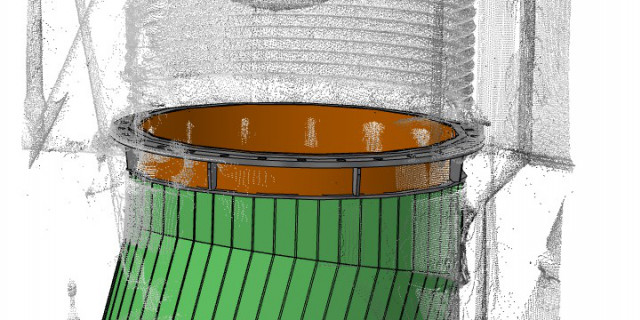

Discretization is the first step in creating an FEM simulation. This involves dividing the continuous geometry of the component into a finite number of elements. These elements take on the physical properties of the overall system and are connected to each other by nodes. The number and size of the elements, as well as the density of the mesh, determine the accuracy and computing time of the simulation. A fine subdivision allows for detailed results, but requires more computing resources.

How are boundary conditions defined in FEM?

Boundary conditions are an essential part of FEM simulation because they define the physical limits and interactions of the model. They can include fixed or movable supports, temperature conditions, or applied loads. The correct definition of boundary conditions is crucial for achieving realistic results. They directly influence the calculation of deformations and stresses and must be carefully selected to reflect the physical conditions of the real system.

Which solvers are used in FEM simulations?

Solvers are algorithms that solve the system of equations in the FEM simulation. There are different types of solvers, including direct and iterative methods. Direct solvers solve the system of equations by direct calculation, while iterative solvers use approximation methods to arrive at the solution step by step. The choice of solver depends on the size and complexity of the model and the specific requirements of the simulation. Iterative solvers are often more efficient for large, complex models, while direct solvers are preferred for smaller systems.

What are the challenges of FEM simulation?

How do approximation methods influence the result?

Approximation methods are an integral part of FEM, as they enable the solution of complex differential equations. However, these methods carry the risk of inaccuracies, especially if the mesh is not sufficiently fine or the approach functions are incorrect. The challenge is to find a balance between computational effort and accuracy in order to achieve reliable results that correctly reflect the physical conditions of the model.

What are the most common problems with meshing?

Meshing is crucial for the accuracy of FEM simulations. Common problems include insufficient mesh fineness, inconsistent element geometries, and inadequate node distribution. These problems can lead to incorrect calculation results and compromise the physical correctness of the simulation. Careful planning and adjustment of the mesh are necessary to overcome these challenges and ensure the accuracy of the simulation.

How can physical behavior be correctly mapped?

Correct mapping of physical behavior in FEM requires precise modeling of material properties and boundary conditions. This includes taking into account non-linear properties such as plastic behavior or thermal expansion. Modern FEM software offers advanced models to take these complex phenomena into account and enable realistic simulations. The challenge is to select the right models and parameters to replicate physical reality as accurately as possible.

What advantages does FEM simulation offer companies such as KSK GmbH?

How does FEM simulation save costs in metal construction?

FEM simulation offers significant cost savings in metal construction by optimizing designs prior to production. Companies such as KSK GmbH can shorten development cycles by using FEM. This reduces project costs, which ultimately leads to greater competitiveness.

What improvements does FEM bring to product development?

In product development, FEM enables detailed analysis and optimization of designs before they go into production. This method provides deeper insights into the physical behavior of components under various load conditions, resulting in more innovative and efficient products. FEM helps engineers identify weaknesses early on and make design changes that significantly improve the performance and reliability of the final product.

How does FEM increase efficiency in component calculation?

FEM increases efficiency in component calculation by providing fast and accurate analysis tools. By automating complex calculations and enabling multiple design variants to be tested quickly, engineers can make informed decisions and significantly reduce development time. FEM makes it possible to simulate complex physical phenomena that would be difficult or impossible to capture using traditional calculation methods, offering a decisive advantage for component optimization.

Analysis and Advice

Project management

Commissioning of Plants

Safety Engineering

Technical Documentation

Conceptual Engineering

Conceptual Engineering

Engineering Office

3D Measurement

Reverse Engineering

CFD Simulation

Structural Steel Statics

Table of contents

- Q: What is FEM simulation?

- Q: How does the finite element method work?

- Q: What applications does FEM have in the steel industry?

- Q: What role does KSK GmbH play in FEM simulation?

- Q: What are the advantages of using FEM in the metal construction industry?

- Q: What are the mathematical principles behind FEM?

- Q: What is the significance of meshing in FEM calculations?

- Q: What influences and boundary conditions must be taken into account in FEM?

- Q: How does FEM contribute to the development of water-cooled plant systems?

Q: What is FEM simulation?

A: FEM simulation is a numerical method for solving complex physical problems by representing the physical behavior of a component through discretization into finite elements. FEM simulation, or the finite element method, is frequently used in engineering and applied mathematics to analyze stresses, deformations, and other physical properties of materials and structures under various load conditions. By dividing a complex geometric problem into smaller, simpler elements, the method can solve the equations of continuum mechanics numerically.

Each of these finite elements is connected by nodes, and within each element, physical properties such as displacement, temperature, or pressure can be described approximately. The totality of these individual calculations provides a comprehensive picture of the behavior of the entire component under specific conditions.

A key advantage of FEM is its flexibility. It can be applied to problems in various fields such as structural mechanics, thermodynamics, and electromagnetism. Modern software packages enable engineers to perform complex simulations that can take into account both linear and nonlinear material behavior.

However, careful modeling and the correct selection of element types and mesh fineness are crucial for a successful FEM analysis. A fine mesh can lead to more accurate results, but requires more computing power and time. Therefore, it is often a balancing act between accuracy and computational effort.

Overall, FEM simulation offers a powerful way to predict the behavior of structures and materials, which is invaluable in the development and optimization of products and buildings.

Q: How does the finite element method work?

A: The finite element method works by dividing a component into a large number of small, easy-to-calculate elements. These elements are connected by nodes and allow the calculation of deformations and stresses under various loads. The finite element method (FEM) enables engineers and scientists to analyze and solve complex physical problems by breaking large structures down into smaller, manageable parts. Each of these small elements is described by simple equations that take into account its physical properties such as stiffness, density, and thermal expansion.

When an external load or internal stress acts on the component, the displacements and stresses at the nodes are calculated. This information is then used to determine the reactions of the individual elements. By combining the results of all elements, a comprehensive picture of the deformations and stress distributions throughout the component can be created.

FEM is used in many areas of engineering and applied mathematics. It is of crucial importance in mechanical engineering, civil engineering, aerospace engineering, and the automotive industry. By providing accurate predictions of the behavior of complex structures under real-world conditions, the finite element method helps to develop safer and more efficient designs.

The development of more powerful computer hardware and specialized software has greatly expanded the application of FEM, allowing even larger and more complex problems to be solved. Modern FEM software offers user-friendly interfaces and advanced features such as nonlinear analysis, dynamic simulation, and optimization techniques that enable users to gain even more detailed and specific insights into their designs.

Q: What applications does FEM have in the steel industry?

A: In the steel industry, FEM is used to optimize metal structures and welded constructions, analyze deformations, and predict the service life of components under various load conditions. In addition, the finite element method (FEM) plays a crucial role in improving production processes and the quality of end products. By simulating thermal and mechanical loads, engineers can identify potential weak points in the design at an early stage and make appropriate adjustments. This not only increases the safety and reliability of the products, but also saves costs by reducing material waste and reworking.

Another important application of FEM in the steel industry is the development of new alloys and materials. By simulating different scenarios, researchers can better understand and optimize the effects of alloy additives on the mechanical properties of steel. This enables the production of materials that are specifically tailored to the requirements of certain applications, such as increased corrosion resistance or greater strength combined with low weight.

In summary, FEM contributes significantly to the innovative strength and competitiveness of the steel industry by supporting well-founded decisions in product development and process optimization.

Q: What role does KSK GmbH play in FEM simulation?

A: KSK GmbH, based in Haltern am See, uses FEM simulation to develop and optimize water-cooled plant systems in order to increase the efficiency and reliability of its products. FEM simulation, or the finite element method, enables KSK GmbH to precisely model and analyze complex physical processes. By simulating fluid dynamics and thermal loads, engineers can identify potential weak points and make design adjustments before physical prototypes are built. This not only shortens development time but also significantly reduces costs.

In addition, KSK GmbH's FEM simulation allows various scenarios to be tested to ensure the performance of its systems under extreme conditions. This is particularly important in applications where reliability and durability are crucial, such as in energy generation or industrial cooling processes.

By using these advanced simulation techniques, KSK GmbH is positioning itself as an innovative market leader in its field, offering its customers high-quality and optimized solutions. At the same time, the use of such technologies contributes to sustainability by using resources more efficiently and minimizing the ecological footprint of products.

Q: What are the advantages of using FEM in the metal construction industry?

A: FEM enables metal fabricators to analyze and optimize the structural integrity of designs, resulting in safer and more efficient designs. In addition, the finite element method (FEM) helps to achieve material savings by enabling more accurate predictions of component behavior under various load conditions. This is particularly important in today's world, where sustainability and resource conservation are becoming increasingly important. By simulating different scenarios, metal fabricators can identify and eliminate potential weak points during the design phase before physical prototypes are created. This not only reduces costs but also significantly shortens development time.

Another advantage of FEM is the ability to take into account complex geometries and nonlinear material properties that would be difficult to analyze using conventional calculation methods. This opens up new design possibilities and enables more innovative and customized solutions. However, integrating FEM into the work process also requires appropriate training and experience in order to interpret and implement the results correctly. Overall, FEM is an indispensable tool in modern metal construction that significantly improves the quality, safety, and efficiency of construction projects.

Q: What are the mathematical principles behind FEM?

A: The mathematical principles of FEM involve solving differential equations using numerical methods such as the approximation method and the weighted residual method. The mathematical principles of the finite element method (FEM) involve solving differential equations using numerical methods such as the approximation method and the weighted residual method. These approaches make it possible to model and analyze complex physical problems that are difficult to solve analytically. FEM breaks down a continuum into a finite number of elements, approximating the solution within each element using special approximation functions, often polynomial functions.

An essential step in the FEM is the discretization of the problem domain, which means that the continuous problem is converted into a finite-dimensional problem. This is achieved by dividing the problem domain into smaller, manageable parts, called finite elements, and applying the differential equations to these elements. The nodes where the elements meet are crucial for defining the solution to the problem.

The weighted residual method, which includes the Galerkin method, is often used to optimize the approximate solutions. In this context, the residual, the difference between the exact and the approximate solution, is weighted and minimized.

Another important aspect of FEM is the formulation of the element stiffness matrix and the global stiffness matrix of the system. These matrices form the basis for solving the resulting algebraic systems of equations that arise from the discretization. Various numerical integration techniques are used to efficiently calculate these matrices.

In practice, FEM is used in a wide range of engineering applications, including structural mechanics, thermodynamics, electromagnetism, and fluid dynamics. The method is particularly valuable in the aerospace industry, construction, the automotive industry, and biomechanics, where it is used to simulate and optimize components and systems.

Q: What is the significance of meshing in FEM calculations?

A: Meshing is crucial because it divides the geometry of the component into elements. The fineness of the subdivision and the density of the mesh influence the accuracy of the FEM calculation. Meshing is crucial because it divides the geometry of the component into elements. The fineness of the subdivision and the density of the mesh influence the accuracy of the FEM calculation. A finer mesh structure can lead to more accurate results because it is able to map more complex geometries and load concentrations in greater detail. However, a higher mesh fineness also significantly increases the calculation time and computing effort.

A balance between mesh fineness and computing effort is therefore crucial for efficient and accurate analysis. In practice, a refinement method is often used, in which the mesh is made finer in critical areas of the component, such as at points with high stress concentrations or complex geometries. In less critical areas, the mesh can be kept coarser to save resources.

In addition to mesh fineness, the type of elements used also plays a role. Different element types, such as linear or quadratic elements, can have different advantages and disadvantages depending on the application. Quadratic elements generally offer higher accuracy in the representation of curvatures and complex shapes, while linear elements are easier and faster to calculate.

Choosing the right meshing and element types is therefore a crucial step in the FEM process, requiring both in-depth technical knowledge and experience. Engineers and analysts must carefully weigh up the options to achieve the optimum balance between accuracy and efficiency, ultimately leading to more reliable and economical design solutions.

Q: What influences and boundary conditions must be taken into account in FEM?

A: In FEM, physical influences such as loads, material properties, and boundary conditions that affect the physical behavior of the component must be taken into account. In the finite element method (FEM), it is crucial to ensure accurate modeling of physical influences in order to obtain valid and reliable results. Loads can be static or dynamic and must be precisely defined according to their nature and effect on the component. Material properties such as elastic modulus, Poisson's ratio, density, and strength are also of central importance, as they determine the reaction of the material to the forces acting on it.

Boundary conditions play an important role as they restrict the movement of the component or allow certain movements. These can be formulated as fixed constraints, free supports, or symmetrical conditions. Careful definition of the boundary conditions is necessary to ensure realistic simulations.

Furthermore, the geometry of the component and the level of detail of the mesh structure must be taken into account when creating the FEM mesh. A finer mesh structure can provide more accurate results, but requires more computing power and time. It is therefore important to find a balance between accuracy and efficiency.

After modeling and simulation, result interpretation and validation are crucial steps in verifying the accuracy of the simulation. Comparative studies with experimental data or analytical solutions can help ensure the quality and reliability of the FEM results.

Q: How does FEM contribute to the development of water-cooled plant systems?

A: FEM helps in the development of water-cooled plant systems by simulating and optimizing thermal and mechanical loads to improve the efficiency and longevity of the systems. The finite element method (FEM) enables engineers to create detailed models of water-cooled plant systems that take into account both the materials and the specific operating conditions. By simulating various scenarios, critical areas can be identified where thermal stresses or mechanical loads could lead to potential failures.

Another advantage of FEM is the ability to quickly evaluate different design options. This not only saves time and money, but also allows for more precise optimization of the systems. For example, engineers can use FEM analyses to determine how changes in geometry or material selection affect heat dissipation and structural integrity.

In addition, FEM helps maximize cooling performance while minimizing energy consumption. By identifying the most efficient cooling strategies, FEM can help reduce the total cost of ownership of plant systems.

In practice, the use of FEM leads to more robust and reliable water-cooled plant systems that can be operated under extreme conditions without the risk of failures or inefficient operating conditions. This is particularly important in industries such as energy or steel production, where the smooth operation of plants is critical to success.