Experience counts.

Our company history gives us the certainty of our relevance and consistency. At the same time, it helps you and us to understand how the company has been able to develop to the high level of performance it achieves today. For almost 40 years, we have been working intensively on the technical, economic and ecological possibilities of plant engineering in order to provide you with optimum benefits and support maximum added value.

Recognize potential.

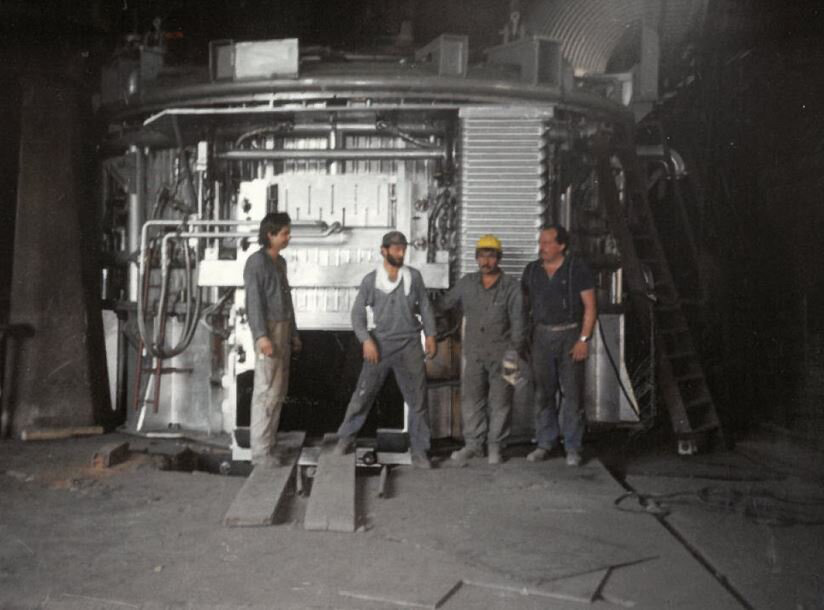

Tubing has always been our "basis of life". It was precisely this semi-finished product that was first used in the 1970s to cool melting pots in the steel industry. Our company founder, Herbert Kuhlmann, recognized the potential of this tube and founded Kuhlmann-System-Kühltechnik GmbH in Bochum-Gerthe in 1983. As a young craft business, KSK initially manufactured individual cooling elements, which replaced the time-consuming and costly brick lining of predestined oven areas. In the years that followed, the experience gained in the meantime by highly qualified employees in production, development and design led to the company developing its own expertise and individual cooling elements became complex water-cooled assemblies and systems.

Use innovations.

Innovative engineering ideas for the optimization of existing plants led to ever closer contacts with plant manufacturers and operators. In 1987, for example, KSK carried out the first complete conversion of an electric arc furnace to increase the tapping weight from 60 to 75 tons. In 1992, KSK was commissioned with the first complete engineering for a new exhaust gas system for three electric arc furnaces.

Enable development.

In 1994, Herbert Kuhlmann left the company for reasons of age. He was replaced by Olaf Huscher and Carsten Oberhag as managing directors and partners. Our production portfolio continued to expand. To take account of this, today's KSK Stahl System Technik was also founded in Brandenburg in 1994 to expand our production capacities. In addition to the traditional core products, we developed ever more complex cooling circuits and complete systems for special applications, with energy efficiency and the extraction of residual energy becoming increasingly important. At the beginning of 2002, a large, modern development and production facility was built in Haltern am See and the company headquarters were relocated.

Promote specialization.

In addition to the production of our systems, our expertise and engineering services increasingly became a pillar in their own right. It therefore made sense to establish our own planning company in 2010. With today's KSK Analyse Planung Design, we have since reached many companies in fields of activity outside our core environment.

The youngest member of the KSK family, KSK Elektro Technik Automation, has been part of the group since 2015. This has made it possible to place complex system solutions with their own control and automation systems on the market.

Shaping the future.

Dipl.-Wirt.-Ing. Andreas Höwedes joined the management team at the beginning of 2019 and replaced Carsten Oberhag as managing director one year later as part of a long-term succession plan. At the beginning of 2021, a holistic restructuring and repositioning of the company and the KSK brand began. In 2022, the portfolio was expanded to include modern simulation methods by Prof. Dr.-Ing. Andreas Wichtmann and the field of structural engineering by Dipl.-Ing. (FH) Patricia Leven-Taron.