Electrical retrofitting and automation of crane systems – your solution for modern crane technology

KSK Automation is your partner for electrical retrofits and the automation of crane systems. With our expertise, we bring your crane systems up to the latest state of the art, increase efficiency, and reduce operating costs through energy recovery units.

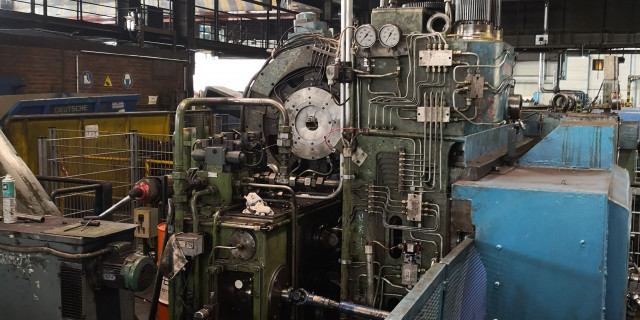

Electrical retrofits for crane systems

We modernize the electrical control and drive technology of your crane systems to optimize their performance. By replacing outdated components and integrating new technologies, we ensure more reliable and energy-efficient use of your cranes.

Automation of crane systems

Increase the precision and efficiency of your crane systems by integrating automated systems. We offer customized automation solutions that simplify your workflows and increase safety.

Replacement of drive technology in the control cabinet

By replacing and modernizing the drive technology in the control cabinet, we optimize the energy consumption and performance of your crane systems. Our solutions ensure improved controllability and a longer service life for your cranes.

New switchgear for your crane

We develop and install modern switchgear that is specially tailored to the requirements of your crane system. This offers maximum safety and efficiency for your lifting technology.

With KSK Automation, you are investing in a future-proof crane infrastructure that increases your productivity and safety. Our customized solutions offer you the flexibility and reliability you need for your crane systems.

Contact us for individual advice and learn more about our range of services in the field of electrical retrofitting and automation of cranes!

Your contact

Thomas Lange

Expert in crane automation

+49 (0) 2364 10539 -134

lange@kskgruppe.de

Table of contents

-

What is crane automation?

- Basics of crane automation

- How does automation work in cranes?

- What role does Schneider Electric play in crane automation?

Intelligent crane automation: transformation by Schneider Electric

Crane automation represents a significant step in the technological transformation of industry. Particular attention is being paid to the integration of intelligent systems in order to increase productivity and efficiency in various areas. Schneider Electric is a leading company specializing in the modernization and automation of crane systems. Through the use of innovative technologies, crane automation offers numerous advantages that increase both safety and efficiency.

What is crane automation?

Basics of crane automation

Crane automation involves the conversion of manually operated crane systems into fully automated systems. These systems incorporate a range of technological innovations, including sensors and software that enable automatic control. The main purpose of automation is to increase the efficiency and flexibility of crane systems while reducing the likelihood of errors. These systems are particularly important in the steel industry, where heavy loads must be handled safely and precisely.

How does automation work in cranes?

The automation of cranes is based on the integration of various technologies that enable precise control and monitoring. Sensors and software are used to record movements in real time and automatically adjust them to ensure optimal positioning of loads. The systems are designed to optimize operations and increase efficiency by minimizing the need for manual intervention. Schneider Electric offers specially developed solutions tailored to the individual requirements of its customers.

What role does Schneider Electric play in crane automation?

Schneider Electric is a leading provider of automation solutions and plays a key role in the transformation of crane systems. The company offers a wide range of products and services that enable the complete automation of crane systems. By using intelligent technologies, including monitoring systems and predictive maintenance, Schneider Electric significantly improves the efficiency and safety of crane systems. The solutions are designed to meet specific customer requirements while reducing operating costs.

How does automation increase the productivity of a crane?

Advantages of automated crane systems

Automated crane systems offer numerous advantages that significantly increase productivity. Automation speeds up processes and optimizes workflows, resulting in greater efficiency. The reduction in manual intervention minimizes the risk of human error and increases operational safety. In addition, automation enables the effective use of resources, which reduces operating costs and increases the competitiveness of companies.

Increased efficiency through intelligent processes

Intelligent processes are an essential part of crane automation and contribute significantly to increased efficiency. Advanced technology allows crane systems to be monitored and controlled in real time. This enables rapid adaptation to changing conditions and increases operational flexibility. Schneider Electric offers solutions specifically designed to optimize workflows, maximizing the productivity of crane systems.

Optimization of workflows

Workflow optimization is a key aspect of crane automation. By integrating automated systems, processes can be made more efficient and the performance of crane systems improved. Schneider Electric offers customized solutions that take into account the individual requirements of customers and maximize workflow efficiency. Automation enables seamless integration into existing infrastructures and improves overall productivity.

What are the requirements for maintaining automated cranes?

Predictive maintenance as the key to efficiency

Predictive maintenance is crucial for maintaining the efficiency of automated crane systems. By continuously monitoring and analyzing the systems, potential problems can be identified and rectified at an early stage before they affect operations. Schneider Electric offers innovative maintenance solutions that extend the service life of the systems and reduce operating costs. Predictive maintenance helps to ensure the reliability and safety of crane systems.

Monitoring and adjusting the systems

Monitoring and adjusting systems is essential to ensuring the optimal performance of automated crane systems. Intelligent monitoring technologies enable data to be collected and analyzed in real time so that adjustments can be made to increase efficiency. Schneider Electric offers solutions that enable systems to be continuously monitored and adjusted to optimize operations and meet customer requirements.

How are maintenance services optimized?

Optimizing maintenance services is crucial to ensuring the efficiency and safety of crane systems. Advanced technologies can be used to automate maintenance processes and reduce response times. Schneider Electric offers customized maintenance solutions tailored to specific customer requirements. These solutions help reduce operating costs and maximize crane system availability.

How is safety ensured in crane automation?

Safety requirements in automation

Safety is an essential aspect of crane automation and requires specific measures to minimize risks. Automated crane systems must meet strict safety requirements to ensure the protection of operators and the environment. Schneider Electric offers solutions that are designed to comply with the highest safety standards and significantly reduce operational risks.

Intelligent monitoring systems

Intelligent monitoring systems play a crucial role in ensuring the safety of automated crane systems. These systems collect and analyze data in real time to identify potential hazards early on and take appropriate action. Schneider Electric offers advanced monitoring solutions that maximize crane system safety and minimize the risk of accidents.

Risk minimization through technology

Minimizing risk through the use of advanced technology is a key aspect of crane automation. By integrating intelligent systems, potential hazards can be identified and avoided before they lead to safety issues. Schneider Electric offers solutions that are designed to reduce operational risks and significantly improve the safety of crane systems.

How does crane automation affect logistics and warehousing?

Efficient warehouse solutions through automation

The automation of crane systems has a significant impact on logistics and warehousing. By integrating automated solutions, warehouse processes can be optimized and efficiency increased. Schneider Electric offers innovative solutions that automate warehouse management and increase productivity. These systems enable precise positioning and handling of loads, which maximizes storage capacity and reduces operating costs.

Automated positioning and handling

The automated positioning and handling of loads is a key advantage of crane automation. Advanced technologies enable loads to be moved precisely and efficiently, significantly improving logistics processes. Schneider Electric offers solutions that automate positioning and handling and increase operational flexibility. These systems are designed to meet customer requirements and maximize the efficiency of logistics processes.

Integration into existing logistics processes

The integration of automated crane systems into existing logistics processes is crucial for increasing efficiency and productivity. Schneider Electric offers customized solutions that can be seamlessly integrated into existing infrastructures. This integration enables effective use of resources and maximizes the overall efficiency of logistics processes. Automation offers customers the opportunity to benefit from state-of-the-art technology and increase their competitiveness.

Frequently asked questions on the topic of “crane automation”

Table of contents

- Q: What does crane automation mean?

- Q: What are the advantages of crane automation?

- Q: How can companies upgrade their existing crane systems?

- Q: What role does digitalization play in crane automation?

- Q: What are some specific applications for automated cranes?

- Q: What services do crane automation providers offer?

- Q: What new technologies are used in crane automation?

- Q: How can crane automation help increase safety?

- Q: What options are available for customizing crane automation solutions?

Q: What does crane automation mean?

A: Crane automation refers to the use of technological solutions to operate cranes fully automatically, thereby increasing operational efficiency and minimizing human error. Crane automation refers to the use of technological solutions to operate cranes fully automatically, thereby increasing operational efficiency and minimizing human error. These advanced systems use a combination of sensors, cameras, GPS technology, and real-time data processing software to ensure precise movements and load handling. Automated cranes are capable of performing complex tasks without human intervention, which reduces the risk of accidents and increases workplace safety.

In addition, crane automation enables improved resource utilization as machines operate optimally and downtime is minimized. The implementation of such systems can also lead to cost savings as fewer personnel are required for operation and monitoring, while the service life of the equipment is extended through efficient use.

Crane automation is becoming increasingly important in various industries, such as construction, shipping, and warehousing. Companies that invest in these technologies benefit from increased productivity, improved safety, and greater competitiveness in the market. The integration of artificial intelligence and machine learning into these systems also promises further advances by improving the ability of cranes to adapt to different environmental conditions and specific task requirements.

Q: What are the advantages of crane automation?

A: Crane automation enables companies to benefit from increased operational efficiency, improved safety in hazardous environments, and access to real-time data. The introduction of automated crane systems allows companies to reduce human error and increase precision in complex lifting and transport tasks. With the integration of sensors and IoT technologies, cranes can continuously collect operational data that can be used for predictive maintenance and workflow optimization. This not only extends the service life of the equipment, but also minimizes downtime and maintenance costs.

In addition, crane automation contributes to improved safety by reducing the risk of workplace accidents. Automated systems can be used in hazardous or hard-to-reach areas, exposing personnel to fewer dangers. The ability to control cranes remotely offers additional flexibility and safety, especially in environments with extreme conditions or hazardous materials.

Another advantage is the scalability of automated crane systems. Companies can easily adjust their capacities to respond to changing requirements and growth opportunities. With access to real-time data, managers can make informed decisions that increase productivity and reduce operating costs.

In summary, crane automation not only improves efficiency and safety, but also plays a strategic role in the digital transformation of companies. By integrating these technologies, companies can become more competitive and better adapt to constantly changing market requirements.

Q: How can companies upgrade their existing crane systems?

A: Companies can upgrade their existing crane systems by integrating new technical components and software solutions that enable full automation. Companies can upgrade their existing crane systems by integrating new technical components and software solutions that enable full automation. This offers numerous advantages, including increased efficiency, improved safety, and reduced operating costs. By using state-of-the-art sensor technology and advanced algorithms, cranes can be controlled more precisely, minimizing the risk of human error. At the same time, real-time data analysis enables predictive maintenance, reducing downtime. The automation of crane systems can also increase production flexibility by enabling rapid adaptation to changing requirements. Companies that invest in these technologies can increase their competitiveness and better prepare for future challenges in the global market.

Q: What role does digitalization play in crane automation?

A: Digitalization enables the collection and analysis of real-time data, which facilitates the detection of problems and the optimization of machine performance. The collected data can be used to implement preventive maintenance measures that minimize downtime and extend the service life of machines. In addition, digitalization opens up new possibilities for process automation, which further increases efficiency and reduces human error. Through the use of artificial intelligence and machine learning, systems can learn independently and adapt to changing conditions, increasing the flexibility and responsiveness of companies. Overall, digitalization helps secure competitive advantages and develop innovative business models that meet the ever-changing demands of the market.

Q: What are some specific applications for automated cranes?

A: Automated cranes are used in various applications, including shipping, production centers, and the handling of hazardous materials. Automated cranes offer numerous advantages in these areas. In shipping, they enable more efficient handling of goods by speeding up the loading and unloading process and minimizing human error. In production centers, they help optimize internal logistics by transporting raw materials and finished products to the right places with precision and reliability. When handling hazardous materials, automated cranes significantly increase safety by reducing direct human contact with potentially dangerous substances or environments.

In addition, automated cranes are often equipped with advanced technologies such as sensors, cameras, and artificial intelligence. These technologies enable improved monitoring and control, resulting in greater accuracy and efficiency. Such systems can also be integrated into existing digital infrastructure to ensure seamless communication and coordination with other automated processes.

Despite the initial investment costs, automated cranes offer significant cost savings in the long term. They reduce the need for manual labor, minimize the risk of workplace accidents, and increase productivity through continuous operation without breaks. Overall, they help to increase the competitiveness of companies and make their operations future-proof.

Q: What services do crane automation providers offer?

A: Providers offer a broad portfolio of services, including the installation of automation solutions, technical support, and the adaptation of programs to specific customer requirements. In addition, the portfolio often includes training for employees to ensure the effective use of the new technologies. Providers work closely with their customers to develop customized solutions that meet individual business processes and goals. This can include the integration of new systems into existing IT infrastructures and the optimization of workflows. To meet the constantly changing requirements of the market, providers continuously invest in research and development to offer innovative and future-proof solutions. In addition, many companies also offer regular maintenance and update services to ensure the performance and safety of the implemented systems.

Q: What new technologies are used in crane automation?

A: The latest technologies in crane automation include advanced sensor technology for obstacle detection and specialized software for the management and integration of fully automated control systems. In addition, artificial intelligence (AI) and machine learning are also being used to optimize operating processes and improve efficiency. The use of IoT (Internet of Things) technologies allows cranes to be monitored and maintained in real time, reducing downtime and increasing safety. Augmented reality (AR) is increasingly being used to provide visual support to operators and technicians during maintenance and training. The integration of all these technologies makes it possible to make cranes not only more autonomous but also smarter by enabling them to adapt to changing conditions and work more efficiently. Another trend is the development of remote-controlled and teleoperated crane systems that allow cranes to be operated from a safe distance, which not only increases personnel safety but also facilitates operation in hazardous environments.

Q: How can crane automation help increase safety?

A: Crane automation reduces the need for human intervention in hazardous environments, minimizes accidents, and ensures the safe handling of heavy loads. In addition, automation increases efficiency and productivity by enabling precise movements and optimizing operating times. The integration of advanced sensors and control systems allows the condition of the load and the environment to be monitored in real time, leading to better decision-making. Companies benefit from reduced operating costs and can use their resources more effectively. In addition, crane automation enables continuous monitoring and maintenance, extending the service life of the equipment and minimizing maintenance costs. Overall, automation helps to increase the competitiveness of companies while improving the safety and comfort of workers.

Q: What options are available for customizing crane automation solutions?

A: Customization options include programming specific functions, integrating local control systems, and adapting to specific operational requirements. Customization options include programming specific functions, integrating local control systems, and adapting to specific operational requirements. In addition, companies can take advantage of training and support services to ensure that the implemented system is used optimally. Close collaboration with vendors can also help develop customized solutions tailored to the individual needs and challenges of each company. Furthermore, regular updates and maintenance can continuously improve the performance and security of the systems. The flexibility of such systems enables companies to respond quickly and efficiently to changes in the business environment.

Data Export from S7 Controllers

Retrofit

Control cabinet construction