Table of contents

-

What can KSK Analysis Planning Design do for you in the field of CFD simulations?

- Undiscovered treasures.

- Gain clarity.

- Your contact

What can KSK Analysis Planning Design do for you in the field of CFD simulations?

Undiscovered treasures.

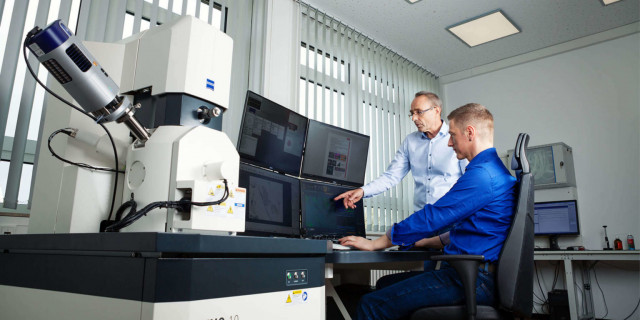

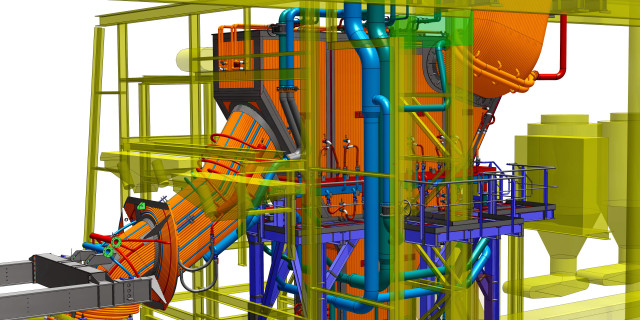

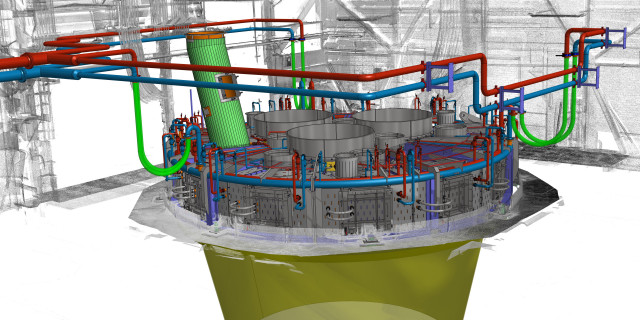

Experience is good, simulation is better? The combination is what counts! Only in this way can colorful images with flow lines of cooling water and exhaust gas volume flows and heat distributions from a computational fluid dynamics (CFD) simulation become real treasures that can reveal previously undiscovered things.

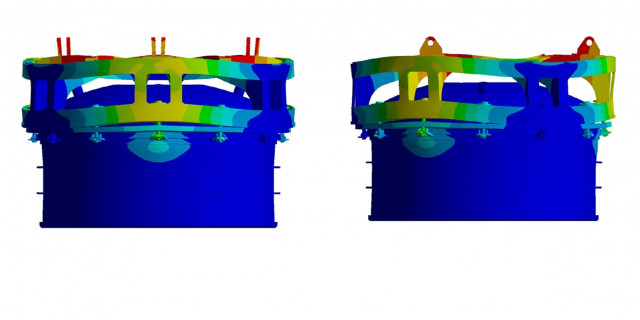

And only then can you be sure that the measures we recommend following a CFD simulation are also feasible and effective in terms of manufacturing and design. We are also able to perform structural analysis using the finite element method (FEM).

Gain clarity.

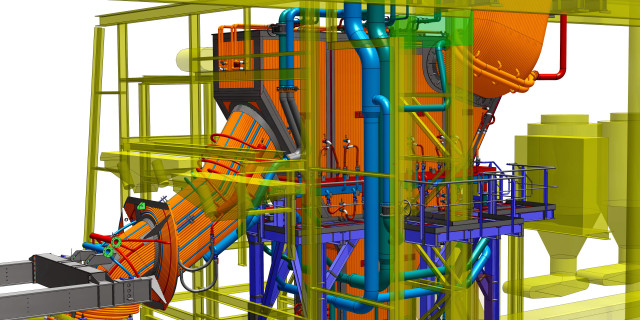

In addition to providing new insights into the optimization potential of existing plants, our CFD simulations and FEM analyses provide clarity about the technical feasibility and safety of plants, especially in large new construction or conversion projects.

Your contact

Prof. Dr.-Ing. Andreas Wichtmann

Simulation and FEM

+49 (0) 2364 10539-0

What is CFD and how does a CFD simulation work?

Definition of CFD and flow simulation

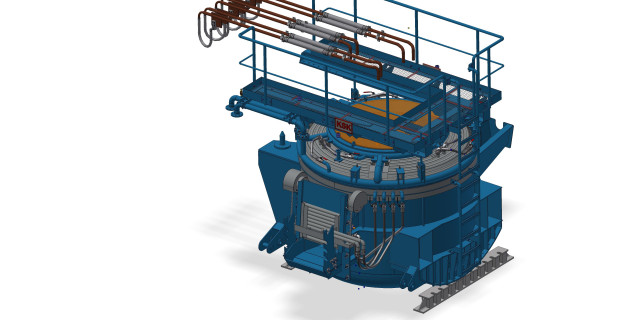

CFD, or computational fluid dynamics, is a discipline of fluid mechanics that deals with the modeling and calculation of flows using numerical methods. Flow simulation makes it possible to simulate the behavior of liquids and gases under various conditions. The physical forces acting on the fluids, such as pressure and temperature distribution, are taken into account. These simulations are often used to analyze complex systems such as pipelines, pumps, and valves and to increase their efficiency. CFD simulations enable companies such as KSK Analyse Planung Design to optimize the efficiency and aerodynamics of products, thereby significantly advancing product development.

Fundamentals of numerical fluid mechanics

Numerical fluid dynamics is based on the solution of the Navier-Stokes equations, which describe the motion of liquids and gases. These equations are complex and require powerful computing resources and CFD software to solve them. The use of solver algorithms and numerical methods is crucial to ensure the accuracy of the simulation results. By modeling the flow around a model and taking thermal effects into account, engineers can make precise predictions about the behavior of fluid systems.

How do you calculate flows with CFD software?

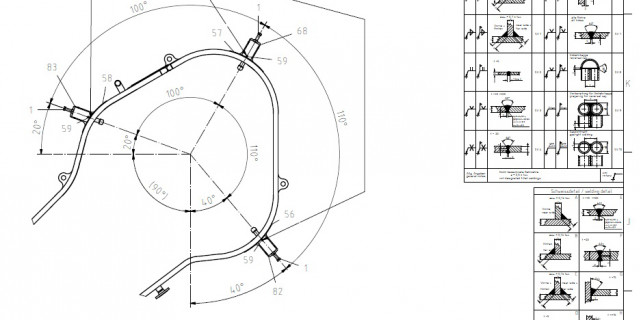

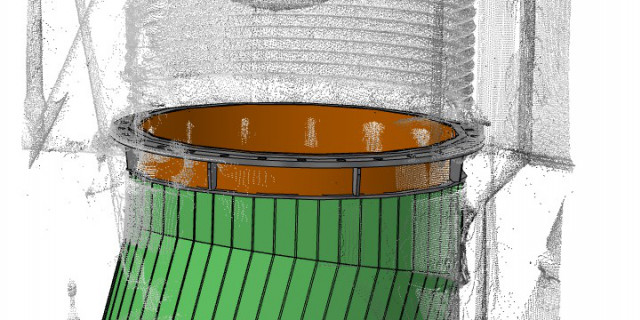

CFD software makes it possible to calculate flows by creating geometric models and applying numerical methods. These software tools use CAD data to model the geometries of products and employ numerical solvers to simulate the fluid dynamics. The calculation involves discretizing the flow domain and solving the relevant physical equations. By visualizing the simulation results, engineers can evaluate the effectiveness of their designs and make optimizations.

Why is CFD important in product development?

Advantages of CFD simulation in prototype optimization

CFD simulations offer numerous advantages in product development, especially in the optimization of prototypes. They enable engineers to simulate the fluid mechanics of a design before physical prototypes are built. This allows companies to save time and money by identifying and resolving potential problems early on. CFD simulations provide a detailed analysis of pressure distributions, temperature profiles, and other critical factors that influence the overall performance of a product.

How does CFD improve product efficiency?

By using CFD software, engineers can significantly increase the efficiency of products. Numerical flow simulation makes it possible to optimize the aerodynamics and heat transfer of products, resulting in better performance and energy efficiency. By analyzing fluid mechanics, potential weak points can be identified and eliminated through targeted adjustments. This leads to improved functionality and longevity of products.

Role of CAD and PLM in flow simulation

CAD (computer-aided design) and PLM (product lifecycle management) play a crucial role in flow simulation. CAD software is used to create precise geometric models of products, which are then imported into CFD software to perform the flow simulation. PLM systems help manage and automate the entire development process by ensuring that all data and simulation results are consistent and accessible. This integration enables engineers to work more efficiently and improve the quality of product development.

What are the challenges of CFD simulation?

Complexity of boundary conditions in numerical simulation

One of the biggest challenges in CFD simulations is dealing with complex boundary conditions. These conditions determine how fluids interact with surrounding structures and must be defined accurately to achieve precise results. Modeling these boundary conditions requires a deep understanding of the physical processes and numerical methods used in CFD simulation. Incorrect boundary conditions can lead to incorrect results and inefficient designs.

How do you deal with pressure losses and thermal effects?

Pressure losses and thermal effects are key challenges in flow simulation, as they can significantly affect the efficiency and performance of a system. CFD software makes it possible to model and analyze these factors in order to identify potential optimizations. The simulations help to understand and minimize the effects of pressure losses in pipes and the distribution of heat in a system. By numerically modeling these effects, engineers can improve product performance and reduce costs.

Common problems in calculation and their solutions

When calculating flows with CFD software, problems such as converging solutions, mesh independence, and computing resource management often arise. These problems can affect the accuracy of the simulation results and must be handled carefully. Thorough validation of the simulation results is necessary to ensure that the models are correct. The use of high-performance computing and advanced algorithms can help overcome these challenges and improve the efficiency of calculations.

What software solutions are available for CFD simulations?

Overview of leading CFD software on the market

There are a variety of CFD software solutions on the market that offer different features and specializations. Leading providers include Siemens and other specialized software developers that focus on numerical flow simulation. These software solutions offer comprehensive tools for modeling, simulating, and analyzing flows, enabling engineers to optimize their designs and accelerate product development.

How do you choose the right CFD software for specific applications?

Choosing the right CFD software depends on the specific requirements of the application and the available resources. Factors such as the type of fluid dynamics to be modeled, the complexity of the geometries, and the required accuracy of the simulation results play a decisive role. Companies must also consider the integration capabilities with existing CAD and PLM systems as well as the user-friendliness of the software to ensure efficient implementation in their development processes.

Integration of CFD simulations into existing engineering processes

The integration of CFD simulations into existing engineering processes can significantly increase the efficiency and accuracy of product development. By seamlessly connecting CAD and PLM systems with CFD software, engineers can create a unified development environment that facilitates data automation and management. This integration makes it possible to quickly analyze and validate simulation results and integrate them into the development process, leading to faster and more accurate design decisions.

How to interpret CFD simulation results?

Fluid dynamics analysis: What do the data tell us?

The analysis of fluid dynamics through CFD simulations provides valuable data that gives insight into the behavior of fluids in a system. This data includes information about pressure distributions, velocity fields, and temperature distribution, which can be used to evaluate the performance of a design. Visualizing this data helps engineers understand complex flow patterns and make targeted adjustments to improve the efficiency and functionality of a product.

How do you verify and validate simulation results?

Validating simulation results is an essential step in the CFD process to ensure the accuracy and reliability of the models. This can be done by comparing the simulation results with experimental data or by performing sensitivity analyses. Validation helps identify potential errors in the models and ensures that the simulations accurately represent the physical processes. Careful validation is crucial for the acceptance and application of CFD results in product development.

Analysis and Advice

Project management

Commissioning of Plants

Safety Engineering

Technical Documentation

Conceptual Engineering

Conceptual Engineering

Engineering Office

3D Measurement

Reverse Engineering

FEM Simulation

Structural Steel Statics

Table of contents

- Q: What is CFD and why is it important for product development?

- Q: What advantages does CFD simulation offer over conventional methods?

- Q: How does computational fluid dynamics work in practice?

- Q: What role does CAD integration play in CFD simulation?

- Q: What are the most common applications of CFD in industry?

- Q: How do boundary conditions influence the results of a CFD simulation?

- Q: What are the challenges of modeling multiphase flows in CFD?

- Q: Why is the validation of CFD simulations important?

- Q: What software solutions are commonly used for CFD simulations?

Q: What is CFD and why is it important for product development?

A: CFD stands for Computational Fluid Dynamics and is a field of numerical fluid mechanics. It enables engineers to simulate the flow of liquids and gases around complex geometries in order to optimize the efficiency and performance of a product. This reduces the need for physical prototypes and can significantly lower costs and development time. CFD is used in a wide range of industries, including automotive, aerospace, energy production, architecture, and mechanical engineering. Another advantage of CFD is the ability to gain detailed insights into flow phenomena that are difficult to measure experimentally. Engineers can analyze and visualize parameters such as pressure, velocity, and temperature at any point within the flow. This enables a deeper understanding of complex processes such as turbulence, heat transfer, and chemical reactions.

Despite its many advantages, there are also challenges associated with the use of CFD. The accuracy of the simulations depends heavily on the quality of the models and numerical methods used. In addition, complex simulations require considerable computing power and can be time-consuming. It is therefore important to make appropriate simplifications and assumptions to ensure efficient yet accurate analysis.

In the future, further developments in computer hardware and algorithms are expected to further improve the capabilities of CFD. The use of machine learning and artificial intelligence could offer new approaches to optimizing simulations that increase both accuracy and speed. This will enable engineers to develop even more innovative and efficient designs.

Q: What advantages does CFD simulation offer over conventional methods?

A: CFD simulation provides a precise way to model the behavior of fluids and gases, which is often difficult in traditional experimental analysis. This allows for detailed analysis of fluid mechanics, heat transfer, and pressure distribution, leading to better optimization and more efficient product development. In addition, CFD simulations can be used in a wide range of industries, including automotive, aerospace, construction, and energy production.

Another advantage of CFD simulations is the ability to test scenarios that would be difficult or impossible to carry out in the real world. Extreme conditions such as high temperatures, pressures, or aggressive chemical environments can be simulated safely and cost-effectively without the need to create physical prototypes.

Increasing computing power and advances in software development have significantly improved the accuracy and speed of CFD simulations. Modern software tools offer user-friendly interfaces and advanced modeling capabilities that enable engineers and scientists to perform detailed simulations with high precision.

However, performing CFD simulations requires a deep understanding of the underlying physical principles as well as the numerical methods used to solve the corresponding equations. Therefore, training and continuing education for professionals in this field is essential to fully leverage the benefits of this technology.

Overall, CFD simulations are a powerful tool that drives both innovation and efficiency in product development and research by providing deeper insights into complex flow processes.

Q: How does computational fluid dynamics work in practice?

A: Numerical flow simulation uses mathematical equations to calculate the behavior of fluids. These equations are solved by CFD software using numerical methods. Engineers define boundary conditions and geometries to achieve accurate simulation results. Numerical flow simulation, also known as computational fluid dynamics (CFD), is an essential tool in modern engineering practice. By calculating flow behavior, engineers and scientists can analyze various scenarios without having to build physical prototypes. This saves time and money and provides insights into complex flow phenomena that are difficult to capture experimentally.

Important steps in the CFD process include creating a geometric model, discretizing the flow space into a mesh or grid, defining the physical properties of the flow, and specifying the boundary and initial conditions. Choosing the right turbulence models and taking into account heat transfer, multiphase flows, or chemical reactions are also crucial factors for the accuracy of the simulation.

Once the model has been set up, the underlying Navier-Stokes equations, which describe the motion of fluids, are solved numerically. This is usually done using iterative methods that can handle the computational effort required by the large number of equations and unknowns. The results of the simulations can then be visualized and analyzed to understand the behavior of the flow and make design improvements if necessary.

CFD is used in a wide range of applications. With the ongoing development of computing power and algorithms, the accuracy and efficiency of CFD simulations is constantly improving, leading to even more realistic models and predictions.

Q: What role does CAD integration play in CFD simulation?

A: The integration of CAD data into CFD simulations is crucial for creating accurate models of products and components. This allows engineers to import geometries directly into the CFD software, making simulations more efficient and accurate. The seamless integration of CAD data into CFD simulations offers numerous advantages. One of the main benefits is the reduction of errors that can occur during the manual transfer of geometry data. By importing CAD data directly, potential inaccuracies are minimized, resulting in more precise simulation results.

Furthermore, this integration enables significantly faster iteration in the design process. Engineers can make changes to the CAD models and test them immediately in new CFD simulations. This shortens development times and improves flexibility in the design process.

Another advantage is improved collaboration between different teams. Since the CAD data flows directly into the simulations, both the design and simulation teams can work in better sync. This promotes more efficient information exchange and speeds up decision-making.

The integration also enables better product optimization. Engineers can quickly simulate different design variants to find the best solution in terms of performance, efficiency, and cost. This leads to more innovative and competitive products.

Overall, the integration of CAD data into CFD simulations represents a decisive step in modern product development. It helps engineers master complex challenges and develop high-precision, high-performance products.

Q: What are the most common applications of CFD in industry?

A: CFD is frequently used in mechanical and plant engineering. Applications include analyzing heat transfer in components and calculating pressure losses in pipes and pumps. In addition, CFD plays a crucial role in environmental engineering, particularly in modeling the spread of pollutants in the atmosphere and in water. The ongoing development of CFD software and the increased computing power of modern computers are enabling increasingly accurate simulations, which help to shorten development times and reduce costs.

Q: How do boundary conditions influence the results of a CFD simulation?

A: Boundary conditions are crucial because they determine the physical limits of the simulation. They include aspects such as inlet velocities, temperatures, and pressure conditions, which greatly influence the accuracy and relevance of the simulation results. Boundary conditions are crucial because they determine the physical limits of the simulation. They include aspects such as inlet velocities, temperatures, and pressure conditions, which greatly influence the accuracy and relevance of the simulation results. Careful definition of these conditions is essential for modeling realistic scenarios and making reliable predictions.

Furthermore, boundary conditions must be consistent with the laws of physics and the specific requirements of the system under investigation. In many cases, this requires iterative adjustment and validation of the initial conditions by comparison with experimental data or by sensitivity analyses.

Boundary conditions play a central role in fluid mechanics and thermodynamics in particular. Choosing the right conditions can make the difference between a simulation that provides valuable insights and one that leads to inaccurate or even misleading results.

Another important aspect is the consideration of boundary conditions when modeling interfaces where different physical phenomena interact. Here, for example, transition conditions between solid surfaces and fluids or between different material layers can be decisive.

Finally, it is also important to consider the effects of boundary conditions on the stability and convergence of numerical solutions. An incorrect specification can lead to instabilities that render the entire simulation unusable. Therefore, a thorough analysis and validation of the boundary conditions is a continuous process that requires special attention throughout the simulation project.

Q: What are the challenges of modeling multiphase flows in CFD?

A: Multiphase flows involving multiple liquids or gases present complex challenges. Accurate modeling requires advanced numerical methods to correctly simulate interactions between the phases, which requires high computing resources. Multiphase flows involving multiple liquids or gases present complex challenges. Accurate modeling requires advanced numerical methods to correctly simulate interactions between the phases, which requires high computing resources.

An essential aspect of modeling multiphase flows is the consideration of phase boundaries, whose dynamics are crucial for the entire flow process. These interfaces can take on complex shapes and change over time, which further complicates simulation. Commonly used methods include the volume-of-fluid (VOF) method, the level set method, and the lattice Boltzmann method. Each of these methods has its advantages and disadvantages, depending on the specific properties of the flow being modeled.

Another critical factor is the accurate determination of the material properties of each phase, such as viscosity and density, as well as their changes under different temperature and pressure conditions. These properties have a significant influence on the flow dynamics and must therefore be precisely integrated into the models.

Due to the complexity of these systems, high-performance computers are often required to perform the necessary calculations within a reasonable time frame. Parallel processing and optimization of the algorithms are crucial to increase the efficiency of the simulations.

In practice, multiphase flows are important in many industrial applications, from the oil and gas industry to chemical process engineering, the development of new materials, and environmental technology. Advances in the modeling and simulation of these complex systems enable engineers and scientists to optimize processes, increase efficiency, and improve plant safety.

Q: Why is the validation of CFD simulations important?

A: Validating CFD simulations is crucial to ensure that the models accurately represent physical reality. This involves comparing simulation results with experimental data or other recognized solutions to ensure the accuracy and reliability of the simulations. Validating CFD simulations is crucial to ensure that the models accurately represent physical reality. To do this, simulation results are compared with experimental data or other recognized solutions to ensure the accuracy and reliability of the simulations.

An important aspect of validation is the selection of suitable test cases that realistically represent both the relevant physical phenomena and the operating conditions. These test cases should include well-documented experimental data that can serve as a reference. The uncertainties in the experimental data must also be taken into account to enable a fair evaluation of the CFD results.

In addition to comparison with experimental data, validation can also be performed using analytical solutions or high-resolution numerical methods. These reference solutions provide an additional benchmark for assessing the performance of the CFD model.

Another important step in the validation process is sensitivity analysis. This helps to understand how different model parameters, such as grid resolution, turbulence models, or boundary conditions, influence the simulation results. By identifying the most sensitive parameters, the modeler can make targeted adjustments to improve the accuracy of the simulation.

Finally, documenting the validation process is crucial to ensure the traceability and reproducibility of the results. Thorough validation strengthens confidence in CFD models and enables their use in critical areas such as steel production, where accurate predictions are of paramount importance.

Q: What software solutions are commonly used for CFD simulations?

A: Commonly used CFD software solutions include ANSYS Fluent, Simcenter STAR-CCM+, and Siemens NX. These offer advanced modeling capabilities, solver technology, and user interfaces to perform complex flow simulations. In addition, they are capable of integrating multiphysics simulations, allowing engineers to analyze not only flow behavior but also heat transfer, reactions, turbulence, and other physical phenomena. These software solutions support a wide range of industries, including energy production and chemical process engineering.

Another important aspect of these tools is their ability to work with high-performance computing (HPC) infrastructures, which enables the processing of large and complex models. This significantly speeds up the development process and helps companies develop more efficient and innovative products.

In addition, many of these software solutions offer user-friendly interfaces and comprehensive documentation that make it easy to get started and reduce the training required for new users. Advanced visualization tools help to better understand and communicate the results of the simulations.

With the continuous development of CFD software, new technologies such as machine learning and artificial intelligence are also being integrated to improve the accuracy of simulations and further optimize the design process. This opens up exciting opportunities for future developments in flow simulation and its application in industry.