Table of contents

-

What can KSK Analysis Planning Design do for you in the field of technical documentation?

- Technical documentation

- Expertly documented.

- Designed for clarity.

- Your contact

What can KSK Analysis Planning Design do for you in the field of technical documentation?

Technical documentation

Technical documentation is an indispensable part of the development and production of modern products. It ensures that information about the product is communicated comprehensively and clearly to the relevant target groups. Whether for internal use or for external partners, technical documentation contributes significantly to safety and efficiency and supports compliance with legal guidelines and standards.

Expertly documented.

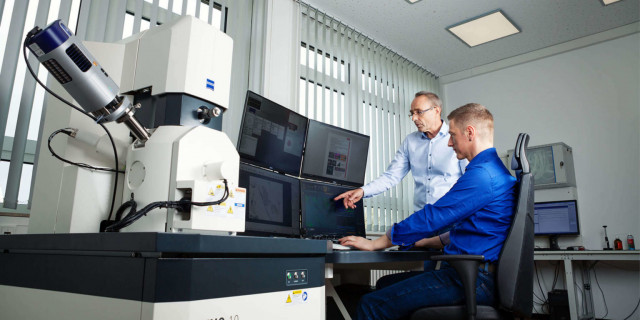

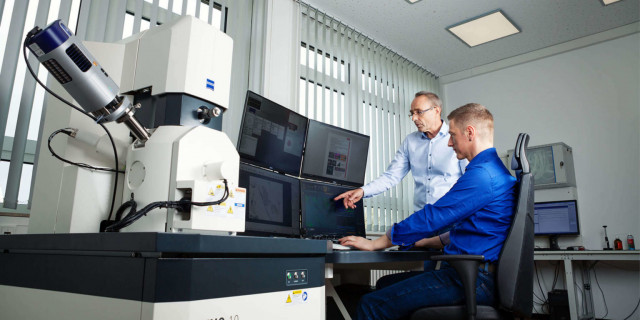

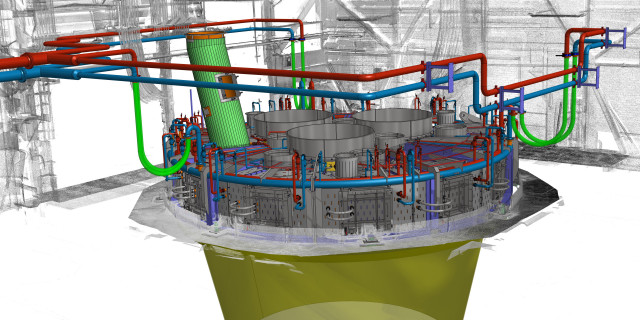

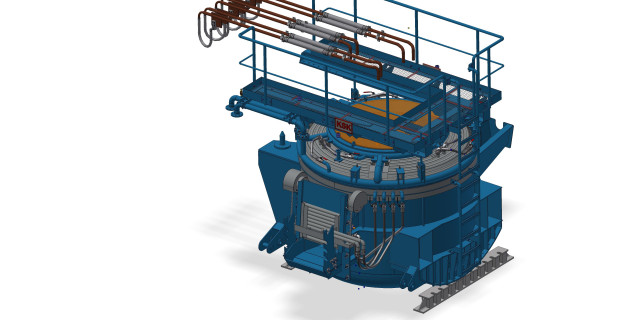

In plant engineering, precise and understandable manuals are essential to ensure the efficiency and safety of your (water-cooled) systems, plants, components, and machines. Our specialized services in the field of manual and technical documentation offer you tailor-made solutions that are tailored to the specific requirements of your plants. You can expect the following from our documentation:

- Expert content: Our experts have extensive knowledge of plant engineering and understand the complex processes of process engineering (and water-cooled) systems. We provide you with accurate and technical information that is easy to understand.

- Customization: Each manual is tailored specifically to your systems and processes to meet the needs of your company.

- Ease of use: We design our manuals to be user-friendly and tailored to the target audience so that your team can quickly access important information – from installation and operation to maintenance.

- Training and support: In addition to creating the manuals, we also offer training to ensure that your team is fully equipped to work with the new documentation.

Designed for clarity.

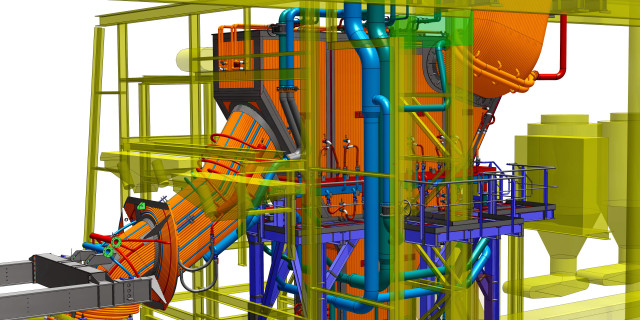

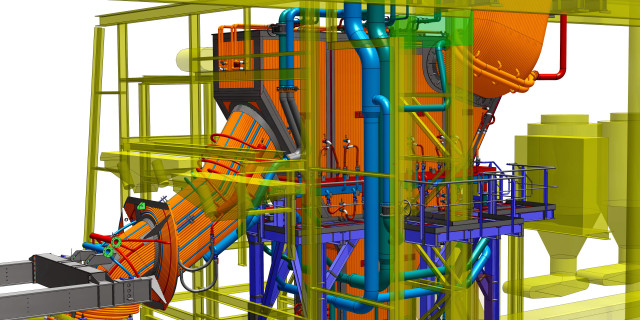

Let's work together to ensure that your (water-cooled) systems can be operated efficiently and safely. A cornerstone of this is comprehensible technical documentation:

- Creation of operating and maintenance manuals

- Creation of functional descriptions and flowcharts

- Creation of drawing documentation

- Documentation of safety guidelines

- Support in the creation of training materials

Your contact

Björn Brüningk-Weißhar, M. Sc.

Head of Engineering

+49 (0) 2364 60897 -20

What is technical documentation?

What does technical documentation include?

Technical documentation comprises a variety of documents that provide detailed information about a product. These documents are essential for the operation, maintenance, and repair of the product. They include operating instructions, maintenance manuals, technical specifications, and safety information. Together, these documents ensure that all aspects of the product are communicated clearly and comprehensively, which is important for both internal and external use.

What role does technical editing play?

Technical editing is a central part of creating documentation. Technical editors are responsible for formulating complex technical information in a clear and understandable way. They make sure that the documentation meets the requirements and is appropriate for the target audience. They pay attention to specific terminology and standards to ensure that the documentation is both legally compliant and user-friendly.

How do internal and external technical documentation differ?

Internal technical documentation is primarily used to train and support employees within a company. It includes documents such as internal manuals and training materials. In contrast, external technical documentation is aimed at customers and business partners and usually includes operating instructions and safety information. Both types of documentation are essential to ensure the smooth operation and correct use of products.

How do you create effective technical documentation?

What steps are important during the creation process?

The creation of technical documentation requires careful planning and execution. Important steps include analyzing the target audience, defining the content, and selecting appropriate media. In addition, technical editors must ensure that the documents comply with the relevant standards and guidelines. Continuous review and updating of the documentation is also crucial to ensure its relevance and accuracy.

How can safety and warning notices be incorporated?

Safety and warning notices are critical elements of any technical documentation. They must be clear and concise in order to inform users about potential hazards and provide them with instructions on how to avoid risks. Technical writers must ensure that these notices are highlighted in the documentation and are easy to understand. The use of pictograms and standardized symbols can help to increase comprehensibility.

What are the requirements for documentation?

The requirements for technical documentation are diverse and depend on the respective industry standards and legal requirements. The documentation must be complete, accurate, and understandable for the target audience. It must contain all relevant information to ensure the safe and efficient use of the product. It must also be structured in a way that facilitates access to the required information.

Which standards and guidelines influence technical documentation?

What is the Machinery Directive?

The Machinery Directive is an important legal requirement within the European Union that regulates the safety of machinery and equipment. It has a significant impact on technical documentation, as it sets specific requirements for the content and structure of documents. Companies must ensure that their documentation complies with the requirements of this directive in order to obtain CE marking and sell their products on the European market.

How does the ISO standard affect documentation?

ISO standards provide an international standard for the quality and consistency of technical documentation. They help establish best practices and ensure that documentation meets uniform quality standards worldwide. Compliance with these standards improves the comprehensibility and accessibility of documents and promotes international cooperation and trade.

What role does the CE marking play?

The CE marking is an essential part of the European single market and indicates that a product complies with applicable EU directives. Technical documentation plays a crucial role in obtaining this marking, as it provides proof of a product's conformity. Compliant documentation is essential for manufacturers to be able to sell their products within the EU.

What is the significance of technical documentation for manufacturers?

How does documentation support product manufacturers?

Technical documentation supports manufacturers by enabling clear and comprehensive communication about their products. It serves as a source of information for customers, service personnel, and other stakeholders, helping to prevent misunderstandings and operating errors. Well-structured documentation can also reduce the burden on customer service and increase customer satisfaction.

What are the advantages of compliant documentation?

Compliant documentation offers numerous advantages for manufacturers. It ensures compliance with legal requirements and standards, which minimizes the risk of legal consequences. It also improves the marketability of a product, as it is regarded as a mark of quality. Compliant documentation can also facilitate international trade and strengthen a company's competitiveness.

What role does the declaration of conformity play?

The declaration of conformity is a crucial document that confirms a product's compliance with the relevant standards and directives. It is an essential part of technical documentation and is required for CE marking. The declaration gives manufacturers the assurance that their products meet legal requirements and can be sold on the market.

Analysis and Advice

Project management

Commissioning of Plants

Safety Engineering

Conceptual Engineering

Conceptual Engineering

Engineering Office

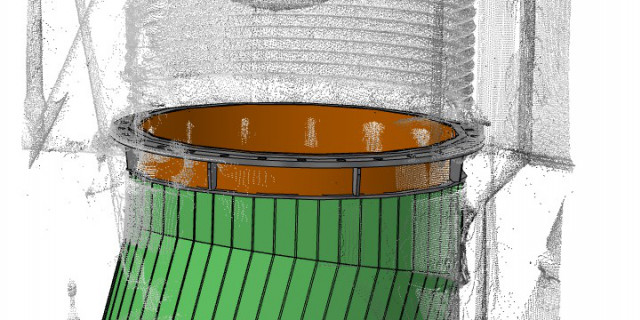

3D Measurement

Reverse Engineering

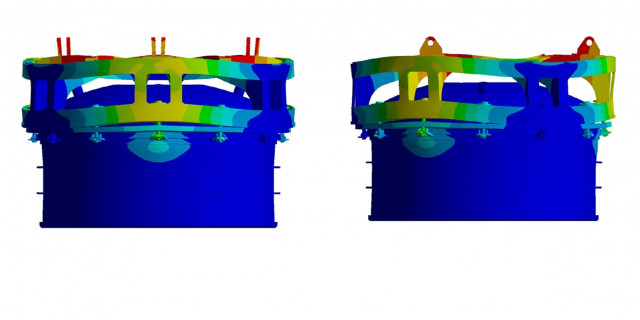

FEM Simulation

CFD Simulation

Structural Steel Statics

Table of contents

- Q: What is technical documentation?

- Q: What role does internal and external technical documentation play?

- Q: Why is it important to create technical documentation?

- Q: What are the components of internal documentation?

- Q: Which documents are included in external documentation?

- Q: What standards are important for technical documentation?

- Q: How does the product life cycle influence technical documentation?

- Q: What is the technical writer's responsibility in documentation?

- Q: What needs to be considered when delivering products?

Q: What is technical documentation?

A: Technical documentation is the comprehensive collection of documents required to support the use, maintenance, and disposal of a product. It includes both internal documentation for the manufacturer and external documentation for the user. Technical documentation is the comprehensive collection of documents required to support the use, maintenance, and disposal of a product. It includes both internal documentation for the manufacturer and external documentation for the user.

Internal documentation usually includes technical drawings, specifications, development reports, and test reports. These documents serve to support the manufacture and quality control of the product by ensuring that all product requirements are met and that the production processes are traceable and efficient.

External documentation is intended for the end user and may include operating instructions, installation instructions, maintenance manuals, safety information, and disposal instructions. The aim is to provide the user with clearly understandable information so that they can use the product safely and effectively. Well-designed external documentation contributes significantly to customer satisfaction and can also meet legal requirements by ensuring that all safety-related information is provided.

In addition, technical documentation plays an important role in product lifecycle management, as it must be continuously updated to reflect changes in product design, new legal requirements, or customer feedback. Modern approaches to technical documentation increasingly use digital technologies to create, manage, and distribute documents more efficiently. These include content management systems, the use of standardized documentation formats such as DITA (Darwin Information Typing Architecture), and the integration of multimedia elements to increase user-friendliness.

Overall, technical documentation is a crucial part of product development and maintenance, helping to ensure the functionality and safety of a product while maximizing user-friendliness.

Q: What role does internal and external technical documentation play?

A: Internal documentation is important for the manufacturer to meet legal requirements such as ISO and DIN EN standards and to ensure compliance. External technical documentation is intended for the user and includes operating instructions and safety and warning notices. External technical documentation plays a crucial role in enabling users to use a product safely and efficiently, as well as minimizing liability risks for the manufacturer. It should be clear, concise, and easy to understand so that users can quickly find the information they need and implement it correctly.

An essential part of the external documentation is the operating instructions, which contain detailed instructions for installing, commissioning, using, and maintaining the product. These instructions should ideally be available in several languages to meet international requirements.

Safety and warning notices are also of utmost importance. They must stand out clearly and point out possible dangers that may arise from improper use of the product. These notices should not only be conveyed in text form, but also through appropriate symbols and pictograms to increase comprehensibility.

In addition to written documentation, audiovisual materials such as video tutorials or interactive instructions can also be provided. These can be particularly helpful in explaining complex processes or difficult-to-understand issues in a clear manner.

To keep the documentation up to date, a regular review and update process should be established. This is particularly important if legal requirements change or the product is further developed. Feedback from users can also provide valuable information for improving the documentation.

Ultimately, well-designed and comprehensive technical documentation not only contributes to customer satisfaction, but also strengthens trust in the brand and can represent a competitive advantage.

Q: Why is it important to create technical documentation?

A: Creating your technical documentation is crucial to ensuring compliance with guidelines and laws, such as the Low Voltage Directive and the Product Safety Act. It is also important for the Product Safety Directive and product liability legislation. Technical documentation serves as proof that your product complies with applicable safety and quality standards. Comprehensive and carefully prepared documentation can serve as crucial evidence in the event of product liability claims. In addition, it facilitates communication with regulatory authorities and can be a decisive advantage during inspections and audits.

The essential components of technical documentation usually include:

1. Product descriptions and specifications: Detailed information about the product, its functions, and technical characteristics.

2. Design drawings and technical plans: Visual representations that illustrate the structure and operation of the product.

3. Hazard assessments and risk management: Documentation of the assessments carried out to identify and minimize potential risks.

4. Operating instructions and user manuals: Clear instructions for the safe and proper use of the product by the end user.

5. Test reports and certificates: Evidence of tests performed and certifications obtained that prove the conformity of the product.

6. Maintenance and repair instructions: Information on maintenance and troubleshooting to ensure the longevity and safety of the product.

Well-structured technical documentation not only supports compliance with legal requirements, but also helps to strengthen customer confidence in your products. It shows that you, as the manufacturer, take responsibility for the safety and quality of your products and continuously improve them.

Q: What are the components of internal documentation?

A: Internal documentation consists of documents such as risk assessments, declarations of conformity, and CE markings that ensure that the product complies with legal requirements before it is placed on the market. These documents are an essential part of a company's quality management system and serve to demonstrate compliance with safety and health requirements. The risk assessment identifies potential hazards that could be associated with the product and evaluates the corresponding risks. Based on this assessment, risk mitigation measures can be developed and implemented.

The declaration of conformity confirms that the product complies with all relevant EU directives, while the CE marking shows that the product complies with European standards for safety, health protection, and environmental protection. This marking is mandatory for many product categories and allows the product to be traded freely within the European Economic Area.

Close cooperation between different departments within a company, including research and development, production, quality control, and legal departments, is necessary to create and maintain the required documents. Regular internal audits and training ensure that all employees are familiar with the latest legal requirements and that company processes are continuously improved.

In addition, it is important to review and update the documentation regularly, especially when changes are made to the products or the relevant regulations. This not only contributes to product safety, but also strengthens the confidence of customers and partners in the quality and reliability of the company's products.

Q: Which documents are included in external documentation?

A: External documentation includes user information such as operating instructions, assembly instructions, and maintenance instructions. These documents help the user to use the product safely and as intended. They are also crucial for training users and service technicians, as they provide detailed instructions and background information. External documentation may also include technical specifications, safety regulations, and declarations of conformity that ensure the product complies with legally required norms and standards.

Another important aspect of external documentation is troubleshooting support. By providing step-by-step instructions and problem-solving strategies, users can resolve minor issues on their own, reducing dependence on technical support and increasing customer satisfaction.

To maximize usability, external documentation should be clearly structured, easy to understand, and written in the language of the end user. Graphics, diagrams, and illustrations can be helpful in visualizing complex information and making it easier to understand.

Overall, well-designed external documentation helps minimize the risk of misunderstandings or misuse, increases product longevity, and strengthens customer confidence in the brand.

Q: What standards are important for technical documentation?

A: Important standards for technical documentation include EN ISO and DIN EN, which define requirements for the quality and safety of documents to ensure the correct and consistent presentation of product information. Important standards include EN ISO 20607, which specifies requirements for the design and content of operating instructions for machinery, and DIN EN 82079-1, which describes general principles for the preparation of instructions for all types of products. These standards help ensure that technical documentation not only meets legal requirements but is also user-friendly and understandable. Another important aspect is risk reduction through clear and precise information that helps users to use the product safely. Compliance with these standards helps companies to minimize liability risks and increase customer satisfaction by providing a reliable source of information.

Q: How does the product life cycle influence technical documentation?

A: The product life cycle influences technical documentation because it must cover all phases from development to operation to disposal. This ensures that all relevant information is available for every stage of the product's life. The product life cycle influences technical documentation because it must cover all phases from development to operation to disposal. This ensures that all relevant information is available for every stage of the product's life.

During the development phase, technical documentation focuses on creating detailed specifications, design descriptions, and test protocols. These documents help engineers and developers clearly understand and implement the product's requirements and functions.

During the market launch and growth phase, the documentation is expanded to include installation instructions, user manuals, and training materials. These documents are crucial for end users and the sales team to effectively market and service the product.

In the maturity phase, the documentation may undergo updates and additions that address customer feedback and further developed product versions. It is important to keep change logs to keep track of all modifications.

Finally, in the decline and disposal phase, the documentation should provide instructions for the safe disassembly and recycling of the product. This is not only important for compliance with environmental regulations, but also to minimize the product's ecological footprint.

Overall, technical documentation throughout the product lifecycle helps to ensure efficiency, safety, and satisfaction for all involved.

Q: What is the technical writer's responsibility in documentation?

A: A technical writer is responsible for the editorial creation and maintenance of technical documentation. This includes ensuring that the documents are clear, concise, and compliant with applicable standards and guidelines. A technical writer is responsible for the editorial creation and maintenance of technical documentation. This includes ensuring that documents are clear, concise, and compliant with applicable standards and guidelines. Their tasks also include working closely with engineers, developers, and other experts to translate complex technical information into understandable and user-friendly instructions and manuals.

In addition, the technical writer is responsible for updating and managing documentation to ensure that all information is up to date and complies with current technical specifications. They use various tools and software to create and manage documents and may also be responsible for translating and localizing documentation into different languages.

Another important aspect of a technical writer's job is quality control. They check documentation for accuracy, completeness, and consistency and ensure that it meets the requirements of the target audience. Technical writers often participate in product training and testing to gain a deep understanding of the products they write about.

In many cases, technical writers are also involved in creating online help systems, tutorials, and other digital content that helps users use products efficiently. This often requires knowledge of content management systems, graphic design, and web technologies.

Overall, technical writers play a crucial role in making complex technical information accessible and understandable to a broad audience, which ultimately contributes to improving the user experience and customer satisfaction.

Q: What needs to be considered when delivering products?

A: When delivering products, all relevant technical documents, such as user manuals and safety information, must be provided to protect people and property and to comply with legal requirements. In addition, it is important that these documents are written in clear and understandable language to avoid misunderstandings. The documentation should be reviewed and updated regularly to ensure that it complies with current standards and regulations.

In addition, products must be manufactured and tested in accordance with applicable quality standards to ensure their safety and functionality. Manufacturers are also responsible for monitoring their supply chains and ensuring that all components and materials comply with legal requirements.

Training for personnel involved in the manufacture, testing, and maintenance of products is also crucial to ensure a high level of quality and safety. In the event of a product recall, clear procedures must be in place to respond quickly and effectively to potential hazards.

Ultimately, compliance with these requirements is not only a legal obligation but also an essential part of corporate responsibility in order to gain and maintain customer trust.