Table of contents

- Submerged Arc Furnace: Electric arc furnace for steel production

-

Submerged Arc Furnace (SAF)

- The KSK SAF

- Cover it up.

- Your Contacts

Submerged Arc Furnace: Electric arc furnace for steel production

In this article, we delve deep into the world of the submerged arc furnace, an indispensable tool in modern metal production. We shed light on how it works, its areas of application, and why it is so crucial for the production of high-quality ferroalloys.

Submerged Arc Furnace (SAF)

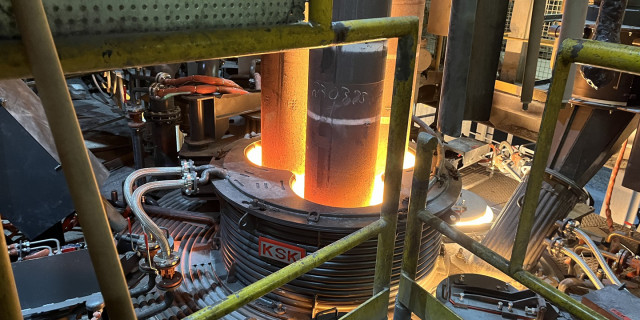

The KSK SAF

The SAF is designed and constructed differently depending on the material being melted, metallurgy, and historical and local conditions. When redesigning or rebuilding your SAF, we at KSK System Kühl Technik take these individual conditions into account and work with you to develop the best possible cooling solution for your unit.

Cover it up.

Depending on the design, many SAFs have a furnace ceiling rather than a swiveling or rotating furnace cover. Whether ceiling or cover, our components are always water-cooled. Due to metallurgical considerations, many of our components in this area are made of copper—usually as welded constructions manufactured in-house.

Due to the many special features of the individual SAFs, the furnace ceiling can be used to implement many different concepts and ideas. Simply contact us and show us your SAF, and together we will find a solution for your cooling challenge.

Your Contacts

Dipl.-Ing. Olaf Huscher

Shareholder-Managing Director

+49 (0) 2364 10539-0

huscher@kskgruppe.de

Dipl.-Wirt.-Ing. Andreas Höwedes

Shareholder-Managing Director

+49 (0) 2364 10539-0

hoewedes@kskgruppe.de

Introduction to the melting reduction furnace

What is a submerged arc furnace?

A submerged arc furnace, often abbreviated as SAF, is a specialized electric arc furnace used in industry to produce ferroalloys or so-called “silicon alloys” and other products from melting reduction furnaces. Unlike an electric arc furnace (EAF), the submerged arc furnace is characterized by the fact that the electrodes are immersed deep into the molten material and the slag floating on top of it, which hides the arcs below the surface of the bath. This special process results in more efficient energy transfer and a reduction in energy loss through radiation. The term “submerged” is derived directly from this submerged operation.

How the submerged arc furnace works

The operation of a submerged arc furnace is based on the generation of intense arcs between the electrodes and the melt. Typically, three-phase alternating current is used to generate these powerful arcs, which heat the melt to very high temperatures. The special feature of the submerged arc furnace is that the electrodes are constantly immersed in the charge, which means that the energy is transferred directly into the melt, while at the same time a protective slag layer above the bath keeps the heat in the furnace. This minimizes the loss of thermal energy and ensures precise control of the reduction process. The resulting products can then be efficiently extracted.

Industrial applications

The products from smelting reduction furnaces are widely used in modern industry, especially in steel production. A submerged arc furnace is essential for the production of ferroalloys such as ferrosilicon, ferromanganese, and ferrochrome, which serve as important alloying elements in steel production to improve certain properties such as strength, corrosion resistance, and hardness. The industrial application of the submerged arc furnace also extends to the production of silicon metal, which is used in the chemical industry and in electronics. The special process of the submerged arc furnace enables high purity and consistency of the products.

Products and materials

Steel production with submerged mixed injection

Metal production in a submerged arc furnace is significantly optimized by the integration of submerged mixed injection processes. This innovative process enables the targeted introduction of gaseous and solid materials directly into the melt and slag. This not only increases the efficiency of the process, but also significantly improves the quality of the ferroalloys and steel produced. The ability to precisely inject reducing agents or alloying elements below the surface of the bath results in a more homogeneous mixture and better utilization of raw materials, making the entire operation of the submerged arc furnace even more effective.

Raw materials used and their properties

Specific raw materials with special properties are essential for operating a submerged arc furnace. These include ores such as quartzite for ferrosilicon, manganese ore for ferromanganese, and chrome ore for ferrochrome. Carbonaceous materials such as coke or charcoal serve as reducing agents, while limestone is often used as a flux to promote the formation of an optimal slag layer. The quality and purity of these raw materials are crucial for the efficiency of the reduction process and the final quality of the products. Careful selection and preparation of the raw materials is therefore a key factor for the successful operation of the submerged arc furnace.

Manufactured end products and their quality

The end products of a submerged arc furnace are mainly high-quality ferroalloys and silicon metal, which play an essential role in modern industry. These products are characterized by their high purity and specific chemical composition, which is precisely tailored to the requirements of subsequent processing steps. For example, ferrosilicon and ferromanganese are used as alloying elements in steel production to improve the mechanical properties of steel, such as strength and corrosion resistance. Continuous monitoring and control of the melting and reduction process in the submerged arc furnace ensure the consistently high quality of these indispensable products.

Advantages of the submerged arc furnace

Efficiency and energy consumption

A key advantage of the submerged arc furnace is its outstanding energy efficiency, which sets it apart from other furnace types such as the EAF. The electrodes are immersed in the molten material and the surrounding slag, completely enclosing the arcs. This minimizes heat radiation and thus significantly reduces energy loss. The direct transfer of energy into the melt ensures optimal utilization of electrical energy, which reduces the specific energy consumption per ton of product. This efficient operation of the submerged arc furnace makes it a cost-effective solution for the production of ferroalloys and other products. The three-phase alternating current systems used in the submerged arc furnace enable precise control of the energy supply, which in turn further increases process stability and efficiency. The continuous and controlled supply of electrical energy ensures uniform heating of the melt. This is crucial for the quality of the ferroalloys or so-called “silicon alloys” produced. Improved thermal efficiency thanks to the unique process of this furnace not only leads to lower operating costs, but also to higher productivity and an overall optimized melting and reduction process on an industrial scale.

Environmentally friendly aspects

Compared to traditional smelting processes, the submerged arc furnace also offers remarkable advantages in terms of environmental friendliness. The submerged operation of the electrodes and the resulting lower release of exhaust gases and dust particles into the atmosphere reduce the environmental impact. The efficiency of energy transfer leads to lower energy consumption and thus a reduction in CO2 emissions per unit produced. This contributes significantly to sustainability in industrial applications and makes the submerged arc furnace a preferred choice for environmentally conscious companies in steel production and beyond. In addition, the design of the submerged arc furnace allows for better control of the by-products generated in the process. The slag produced during the reaction can often be recycled or reused as a valuable material, minimizing the amount of waste. The ability to feed the bath with precise amounts of raw materials and reducing agents not only improves process control but also the efficiency of raw material utilization. These aspects underscore the environmental benefits of the submerged arc furnace and its role as an important component of sustainable industrial processes.

Cost-effectiveness compared to other methods

The cost-effectiveness of the submerged arc furnace is a key factor that makes it a preferred choice in the industry, especially when compared to other processes such as the conventional EAF. The furnace's high energy efficiency, due to the submerged arc process, results in significant savings in operating costs, as less electrical energy is required per ton of product. This is a decisive advantage, as energy costs account for a large proportion of the total cost of production. In addition, the robust design of the submerged arc furnace enables a long service life and reduced maintenance intervals, which brings additional cost benefits. The submerged arc furnace's ability to efficiently process a wide range of raw materials also contributes to its cost-effectiveness. Optimized utilization of raw materials and high product quality minimize losses and maximize the value of the end products. The products from melting reduction furnaces are widely used and in high demand on the market, which ensures a stable value chain. The use of the submerged arc furnace in steel production with submerged mixed injection is further evidence of the ongoing optimization of this process to achieve maximum cost efficiency and productivity.

Challenges and solutions

Common problems when using electric arc furnaces

Despite its numerous advantages, operators of submerged arc furnace plants often face specific challenges. A common problem is uneven heating of the melt, which can lead to inconsistencies in product quality. This is often due to fluctuations in the composition of the raw materials or suboptimal distribution of the electrodes in the melting reduction furnace. Another problem is electrode breakage, which not only leads to costly downtime but can also significantly impair the efficiency of the furnace. Corrosion of the furnace lining by aggressive slag is also a constant challenge that requires regular maintenance and servicing to ensure the longevity of the furnace. Safe operation of the electric arc furnace requires constant attention.

Best practices for optimizing operations

Various best practices have been established to overcome these challenges and optimize the operation of the submerged arc furnace. Precise control of the raw material feed and its composition is crucial to ensure a homogeneous melt and stable slag. Monitoring and controlling the electrode position and three-phase alternating current are also of utmost importance to ensure efficient energy transfer and uniform heating. Regular inspections and preventive maintenance of the furnace lining and electrodes can prevent costly breakdowns and extend the service life of the submerged arc furnace. Continuous training of personnel is essential to ensure that all aspects of operation can be handled optimally.

Technological innovations and future developments

The technology surrounding submerged arc furnaces is constantly evolving to improve efficiency and sustainability. New technological innovations are focusing on improved automation systems for more precise control of the furnace and the melting reduction process. Advances in the development of new electrode materials promise longer service life and greater resistance to breakage, which reduces operating costs. In addition, intensive research is being conducted into the use of waste heat and the integration of renewable energies to further reduce the environmental footprint of the submerged arc furnace. These developments will revolutionize the industrial application of the furnace.

Practical tips for operation

Maintenance and servicing of the smelting reduction furnace

Consistent maintenance and servicing are crucial for the smooth and efficient operation of a submerged arc furnace. Regular inspections of the electrodes, the furnace chamber, and the cooling water circuit should be firmly integrated into the operating routine. Particular attention should be paid to the lining of the arc furnace, as it is subject to heavy wear due to the high temperatures and aggressive slag. Minor cracks or damage should be repaired immediately to avoid major damage and expensive repairs. A detailed maintenance plan helps to minimize downtime and maximize furnace productivity, especially in the production of ferroalloys.

Training of personnel for effective operation

Personnel operating a submerged arc furnace must be comprehensively trained to ensure effective and safe operation. This includes not only understanding the basic functioning of the electric furnace, but also advanced knowledge of the materials science of raw materials and products. Training should include practical exercises on furnace process control, troubleshooting, and emergency procedures. Regular refresher courses ensure that knowledge remains up to date and that new processes and technologies can be used effectively, further improving the safety and efficiency of submerged arc furnace operation.

Efficient monitoring and control systems

Modern monitoring and control systems are essential for the efficient operation of a submerged arc furnace. These systems enable the continuous recording of operating data such as temperature, current, voltage, and gas composition. By analyzing this data, process parameters can be adjusted in real time to optimize energy efficiency and ensure the quality of products from melting reduction furnaces. Automated control systems can also provide early warning of deviations and initiate preventive measures before major problems arise. The investment in advanced monitoring technologies quickly pays for itself through improved productivity and lower operating costs of the arc furnace.

Badschmelzofen

Pfannenofen