Table of contents

- Waste heat recovery

-

What can KSK do for you in the field of waste heat recovery?

- Utilizing waste heat.

- Promoting Ecology.

Waste heat recovery

Waste heat recovery refers to the use of heat that is generated as a by-product of an industrial process. This unused heat can be efficiently utilized in many ways in various industries and companies. Effective waste heat recovery not only makes economic sense, but also helps to conserve resources and reduce environmental pollution.

What can KSK do for you in the field of waste heat recovery?

Utilizing waste heat.

In industry, waste heat is generated in a variety of ways. This applies particularly to the melting and recycling industry. There are many ways to convert waste heat into usable energy. Our closed cooling circuits offer a simple option, using water or steam as a cooling medium from which waste heat can be easily extracted.

Our many years of expertise and our in-depth understanding of the melting and heat-intensive core processes in our customers' plants ensure that all interventions for waste heat recovery in existing systems are carried out without negative consequences for production.

A current publication from us on the topic of waste heat recovery can be found, for example, in the publications of the VIK Verband der Industriellen Energie- und Kraftwirtschaft e.V. from 03/23. The article is available to download here:

Promoting Ecology.

Together with selected partners from the energy industry and technology, we develop holistic concepts for waste heat recovery for you on request, which, in addition to technical feasibility and an ecological and macroeconomic consideration, also includes funding management and all other criteria necessary for an investment decision. Would you like to check whether there is potential for waste heat recovery in your cooling water circuits? Or do you already have a specific idea of how to use the waste heat from your furnace to operate an ORC system? Please do not hesitate to contact us.

The six KSK quality criteria for waste heat recovery.

Clear

Process engineering flowcharts and instructions quickly become complex depending on the application. As a result, supposed secondary processes such as waste heat recovery can easily get lost in the presentation and understanding. To ensure that this does not happen in your plant, our design is always kept as simple as possible and the corresponding documentation and control panels in the control cabinet are clearly laid out.

Functional

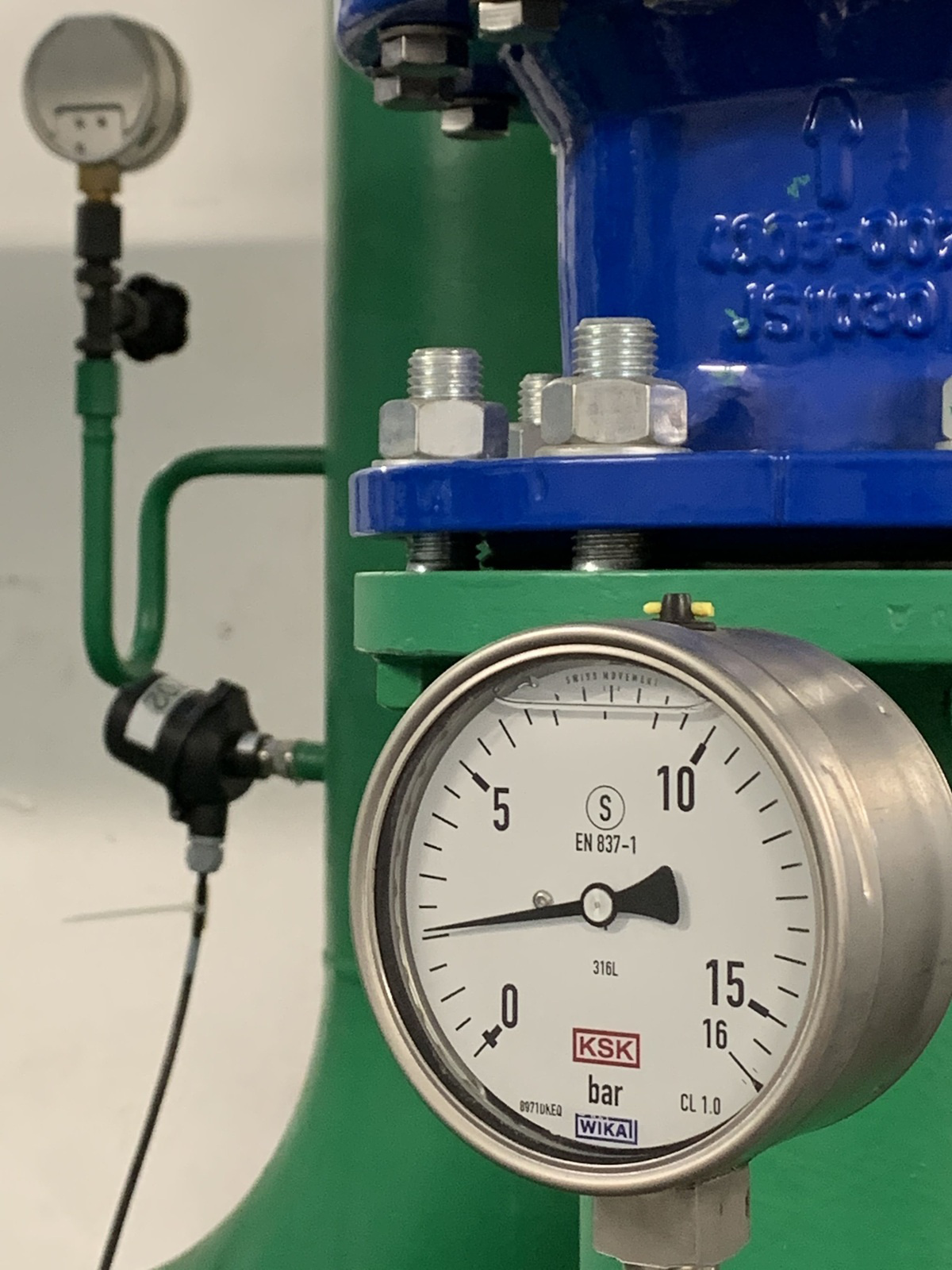

Our technical solutions for waste heat recovery are not off-the-peg. Instead, their functionality is always tailored to the respective circumstances. Is a certain temperature level required to feed the waste heat into a local heating network? Or is the primary process discontinuous, but you need a constant supply of heat for further processing? Is a simple plate heat exchanger sufficient, or would a plate and shell plate heat exchanger be better for high pressures and temperatures? There are often as many solutions as there are questions. It's a good thing that we have already gained some experience in this area, which you are welcome to benefit from.

Innovative

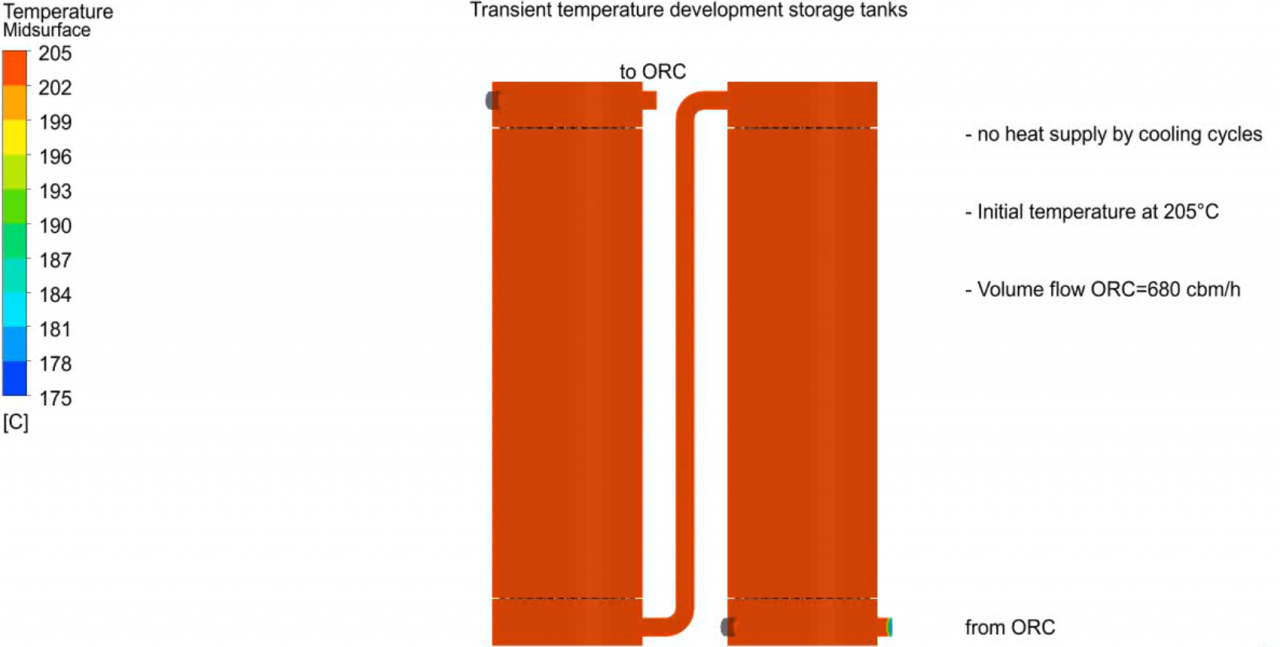

Waste heat is a by-product of many production or other processes. For a long time, it was not given any consideration in further processing. Therefore, innovative approaches and ideas are always needed to capture it, extract it and make it usable. Sometimes a minimally invasive intervention in the existing process technology is enough. In other cases, it may make sense to modify entire components. To clarify these and other questions and to put innovative ideas to the test, we are also happy to support you in advance with a simulation or a corresponding study.

Perfect fit

Working in existing buildings often requires its own unique demands on the accuracy of fit. With our 3D measurement and the most modern construction methods, we install our systems and stations for waste heat recovery in the existing premises with a perfect fit. Whether it's a modular structure, container solution or decentralized design, we will find a clever solution for the space available to you.

Maintenance-friendly

Our waste heat recovery systems are designed for low-maintenance and trouble-free continuous operation, so you can concentrate on the important things in your day-to-day maintenance. Of course, we ensure that all purchased parts installed are absolutely suitable for steelworks.

Cost-effective

Using waste heat as a by-product of production processes sounds good. But does it always make economic sense? Together with selected partners from the energy industry and technology, we develop holistic concepts for waste heat utilization that include technical feasibility, ecological and macroeconomic considerations, funding management and all other criteria necessary for an investment decision. This means that you can reliably estimate in advance of an investment when a plant will potentially pay off and what economic conditions must be in place for it to do so.

What is waste heat recovery and why is it important?

Basics of waste heat recovery in industrial processes

In industrial production processes, such as the production of steel in the steel industry or metal recycling, a significant amount of energy is generated in the form of waste heat. This waste heat often escapes unused into the environment, thus representing a loss of potential energy. The efficient use of this excess heat through technologies such as heat exchangers and heat storage can significantly reduce energy costs and protect the environment.

The role of waste heat utilization for energy efficiency and climate protection

The use of waste heat contributes directly to increasing energy efficiency by reducing the need to generate additional energy for heating systems or to generate process heat. In addition, the reduction in energy demand through the use of waste heat has a positive impact on the climate, as it significantly lowers CO2 emissions. This supports the goals of climate protection across all industries and promotes sustainable production.

How waste heat can help to reduce CO2 emissions

By using waste heat, companies can significantly reduce their carbon footprint. Energy that would otherwise have to be obtained from outside for heating rooms or production processes can be covered by the company's own waste heat. This not only saves energy, but also reduces greenhouse gas emissions. In many cases, the efficient use of waste heat can reduce a company's emissions by up to 30 percent.

Which technologies enable the effective use of waste heat?

Use of heat exchangers and heat storage

Heat exchangers and heat storage are central components in the efficient feeding and use of excess heat in industrial processes. Heat exchangers can transfer waste heat directly from one process to another, while heat storage tanks offer the possibility of storing energy for later use. These technologies make it possible to use the waste heat for heating operating rooms, as process heat or in thermoelectric plants.

Introducing innovative technology for industrial waste heat recovery

Innovations such as thermoelectric generators are opening up new ways of utilizing the energy in waste heat. These devices can convert temperature differences directly into electrical energy, thus providing an efficient way of utilizing previously unused heat. Companies such as KSK GmbH advise and support businesses in selecting and implementing such technologies in order to further reduce energy consumption and emissions.

Examples of applications in companies and their advantages

In the chemical industry or in energy production, waste heat is already being successfully used to increase overall efficiency. For example, heat recovery can be used to reduce the costs of energy production and reduce dependence on fossil fuels. This not only leads to financial savings, but also to a significant reduction in environmental pollution.

How can companies improve their energy efficiency by using waste heat?

Analyzing energy needs and identifying waste heat potential

The first step in improving energy efficiency by utilizing waste heat is to analyze a company's existing energy needs and identify potential sources of waste heat. A detailed examination of production processes and existing facilities can help identify areas with high waste heat potential and develop measures for utilizing these energy sources.

Planning and implementing waste heat recovery projects

Once the sources of waste heat have been identified, careful planning of waste heat recovery projects is essential. This includes selecting suitable technologies, calculating investment costs and expected savings, and considering ecological aspects. Subsidies and financial support from public authorities can help to reduce initial investment costs and facilitate the implementation of waste heat recovery projects.

Investment costs and savings through efficient use of waste heat

Although the initial investment costs for implementing waste heat recovery technologies can be a hurdle, the financial benefits often quickly become apparent in the form of reduced energy costs and lower emissions. In most cases, the investments pay for themselves within a few years, making waste heat recovery not only ecologically but also economically extremely sensible.

Which industries benefit most from waste heat recovery?

Applications in the steel industry and metal recycling

The steel industry and metal recycling are particularly energy-intensive industries where significant energy savings can be achieved through the effective use of waste heat. Reusing the waste heat generated during steel production for other industrial processes or for heating can significantly reduce energy consumption and costs.

Increased efficiency in the chemical industry through heat recovery

The use of waste heat also offers great potential for increasing efficiency in the chemical industry. Heat recovery systems make it possible to recover valuable energy that is generated during chemical reactions and use it to supply energy to the plants. This leads to a significant reduction in energy costs while also promoting environmentally friendly operation.

Examples of successful waste heat recovery in other industrial sectors

Many other industries, including food processing, paper and pulp, and glass manufacturing, also benefit from implementing waste heat recovery projects. Through innovative technologies and customized solutions, efficiency can be increased and a contribution made to environmental protection in almost every industrial sector.

What are the challenges and solutions for industrial waste heat recovery?

Overcoming technical and financial hurdles

The main challenges for waste heat recovery are technical and financial hurdles. Technical challenges include the integration of waste heat recovery systems into existing facilities and processes. Financial hurdles relate to the initial investment costs and ensuring the economic viability of the projects. Solution approaches include the use of subsidies, technical advice from experts and the selection of energy-efficient technologies that lead to long-term savings.

Strategies for maximizing energy savings and environmental impacts

To maximize energy savings and environmental benefits, a holistic approach to waste heat recovery is necessary. This includes continuous optimization of the facilities, training employees to be energy conscious, and integrating waste heat recovery into corporate policy. In addition, cooperation between industry, research and government institutions plays an important role in the development and implementation of innovative solutions.

Expert opinions and best practices in the field of waste heat recovery

Consulting with experts and studying best practices can provide valuable insights into successful waste heat recovery strategies. Numerous companies have already demonstrated that investing in waste heat recovery pays off and yields both financial and environmental benefits. By sharing experiences and working with professionals, businesses can avoid potential pitfalls and optimize the adoption of waste heat recovery systems.

Exhaust gas cooling

Industrial cooling

FAQs on waste heat utilization

Table of contents

- Q: How can the waste heat in industrial plants be used efficiently?

- Q: What economic advantages does the use of waste heat offer companies?

- Q: Can you also generate electricity with waste heat?

- Q: What should be considered when planning a waste heat recovery system?

- Q: What role do renewable energies play in the utilization of waste heat?

- Q: How does the use of waste heat contribute to sustainability?

- Q: Are there examples of successful waste heat utilization in Germany?

Q: How can the waste heat in industrial plants be used efficiently?

A: Industrial plants, especially energy-intensive ones, produce large amounts of excess heat every year. By using heat recovery technologies, this excess heat can be used to heat rooms, produce hot water or even be fed into the local district heating network. The Federal Ministry for Economic Affairs and Energy supports such projects to promote energy efficiency. By using heat recovery technologies, industrial companies can not only reduce their energy costs, but also contribute to climate protection by reducing their CO2 emissions. In addition, they can generate additional income by selling excess heat to third parties.

To facilitate the implementation of such projects, the Federal Ministry for Economic Affairs and Energy offers various funding programs. These include, among other things, grants for the planning and implementation of heat recovery measures, as well as loans and grants for investments in efficient technologies.

By promoting heat recovery in industrial plants, the Federal Ministry for Economic Affairs and Energy is helping to increase energy efficiency in Germany and achieve climate targets. Companies that invest in such measures can not only benefit from the financial advantages, but also make an important contribution to environmental protection.

Q: What economic advantages does the use of waste heat offer companies?

A: Using waste heat can help companies reduce their energy costs, as less energy has to be purchased from external sources for heating or hot water. In addition, companies can benefit from funding and tax advantages. According to the German Energy Agency (dena), operating costs can be significantly reduced, which is particularly interesting for medium-sized companies. In addition, the use of waste heat also offers ecological advantages, as it contributes to the reduction of CO2 emissions. By using heat efficiently, less fossil energy is required, which in turn reduces environmental pollution.

To make effective use of waste heat, companies need to use appropriate technologies such as heat recovery systems or heat pumps. However, these investments can pay off in the long term, as they can lead to a long-term reduction in energy costs and increase the company's competitiveness.

Overall, the use of waste heat offers both economic and ecological advantages for companies. It is therefore worth considering appropriate energy efficiency measures and integrating them into your business strategy.

Q: Can you also generate electricity with waste heat?

A: Yes, by using combined heat and power plants, electricity can also be produced from the excess heat. The steam generated by the use of waste heat is used to drive a turbine. This process can both increase energy efficiency and reduce CO2 emissions. By using combined heat and power plants, the principle of energy efficiency can be improved because the excess heat that would normally be dissipated unused is converted into electricity. This means that less energy is wasted and, at the same time, CO2 emissions can be reduced because less fuel is needed to generate energy.

Combined heat and power plants are particularly efficient in buildings or industrial plants where heat and electricity are needed continuously. By using these plants, a significant contribution can be made to the energy transition, as they help to reduce dependence on fossil fuels and promote renewable energies.

Overall, combined heat and power plants represent a sustainable and resource-efficient way to generate energy and are therefore an important building block for a future climate-friendly energy supply.

Q: What should be considered when planning a waste heat recovery system?

A: When planning a waste heat recovery system, it is important to analyze and understand the entire energy flow of the respective operation. This includes identifying sources of waste heat, heat demand and possible heat utilization paths. It is advisable to consult experts to implement an efficient and sustainable solution. Furthermore, it should be checked to what extent funding programs can be used. Furthermore, it is important to keep an eye on local laws and regulations in order to go through any approval procedures. This also includes taking into account environmental protection requirements and emission guidelines.

When implementing a system to use waste heat, long-term costs and possible savings should also be considered. Investment costs, operating costs and potential savings from using the waste heat are important factors to consider.

Careful planning and implementation of a system for utilizing waste heat can not only lead to cost savings, but also to a reduction in CO2 emissions and thus contribute to sustainable operations. It is therefore important to carefully analyze all aspects of the system and develop a holistic solution.

Q: What role do renewable energies play in the utilization of waste heat?

A: Renewable energies and the use of waste heat complement each other ideally. Integrating systems that use waste heat into existing plants that run on renewable energies can improve the overall efficiency of energy consumption. This further contributes to the reduction of CO2 emissions and to achieving sustainability and climate protection goals. By utilizing waste heat from industrial processes, buildings or power plants, energy can be used more efficiently, thus reducing the consumption of primary energy sources. This not only lowers the cost of energy, but also the environmental impact of using fossil fuels.

In combination with renewable energies such as solar, wind or biomass, the use of waste heat can also help to balance out fluctuations in energy production. For example, heat boilers can be combined with solar thermal energy to ensure a continuous supply of hot water even when there is no sunshine.

In addition, waste heat systems can also help to improve the economic efficiency of renewable energies. This is because the integration of waste heat can reduce the operating costs of renewable energy systems and shorten their payback periods.

Overall, the use of waste heat in combination with renewable energies offers numerous advantages for the environment, the economy and climate protection. It is therefore important to further promote this approach and to implement it more in practice.

Q: How does the use of waste heat contribute to sustainability?

A: The use of waste heat plays an important role in reducing energy consumption and CO2 emissions. By efficiently reusing heat that would otherwise escape unused into the environment, companies contribute directly to the conservation of natural resources and sustainability. This is an important step towards more environmentally friendly production and sustainable economic activity. Waste heat is generated in many production processes, particularly in industry, but also in households and office buildings. It can be used in a variety of ways, for example for heating buildings, in heat recovery processes or for generating electricity using combined heat and power.

By using waste heat, companies can not only reduce their energy consumption and costs, but also contribute to climate protection. This is because lower energy consumption also means lower CO2 emissions, which contribute to global warming.

It is therefore important that companies recognize waste heat as a resource and use it in a targeted manner. Technical solutions such as heat exchangers or efficient heating systems can be used for this purpose. Cooperation with other companies or institutions in the form of heating partnerships can also help to ensure that waste heat is used efficiently and thus relieve the burden on the environment.

Overall, the use of waste heat offers great potential for saving energy and reducing CO2 emissions. Companies that go down this path not only contribute to environmental protection, but can also benefit economically from it. It is therefore important that the use of waste heat is increasingly promoted and driven forward in order to support a sustainable and resource-efficient economy.

Q: Are there examples of successful waste heat utilization in Germany?

A: There are numerous examples of the successful use of waste heat in Germany. One example is the use of waste heat from steelworks to supply neighboring residential areas via a district heating network. Another example is the use of waste heat from data centers to heat office buildings. Such projects show that the technology is not only theoretically worthwhile, but can also be practically implemented and is beneficial. Another example is the use of waste heat from industrial plants for the generation of electricity and heat in combined heat and power plants. Here, the waste heat generated during electricity generation is put to good use to increase energy efficiency and conserve resources.

There are also opportunities for using waste heat in agriculture. For example, the waste heat from biogas plants can be used to heat greenhouses. This can reduce operating costs and CO2 emissions.

Overall, the use of waste heat offers a wide range of opportunities to use energy more efficiently and to protect the environment. Through innovative technologies and concepts, companies and private households alike can benefit from the advantages.