Smooth projects.

Our technical solutions for all melting furnaces, electric furnaces, shaft furnaces or other water-cooled constructions are methodically developed as 3D models as a matter of course. Particularly in brownfield melting furnace conversion projects, a 3D scan carried out beforehand as a measurement allows us to plan designs with millimetre precision, identify interfering edges and avoid collisions even before your melting furnace is installed. This ensures that the project runs as smoothly as possible for you and us and avoids time-consuming and costly surprises during installation.

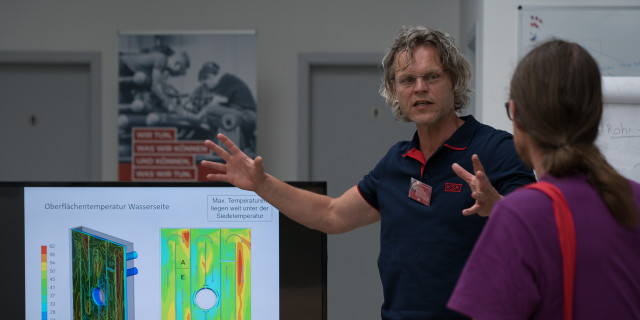

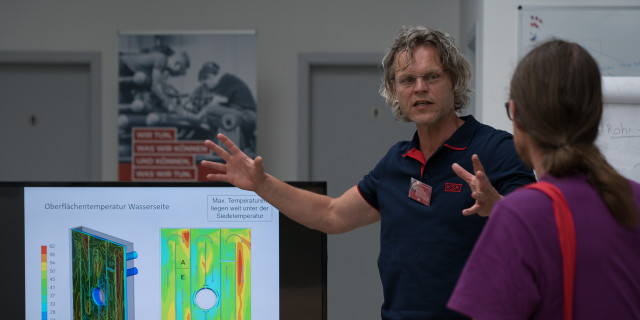

Direct communication.

Following the modeling, we convert our models into 2D drawings ready for production and assembly. All work carried out by our design team is always carried out in close consultation with you and our project and production engineers. And if, contrary to expectations, a small error should creep in: The distance between the design office and the workshop is less than 100 meters.

Harmonize project data.

Would you like to know which tools we rely on when working with your melting furnace or shaft furnace? You can find a list here. Do you have project data from other systems? Our IT specialists speak your language. Get in touch with us!

- Autodesk Inventor 2022

- Autodesk Mechanical 2022

- Autodesk Plant 3D 2022

- Faro X30 3D Scanner

- Autodesk Recap 2022

- ClearEdge3D Edge-Wise

Your contact person